Recently one of our diver/technician teams performed a successful propeller blade cropping operation on a 247-meter tanker while the vessel was in Singapore. Because of the severity of the damage, cropping was the only option.

When the propeller blades of the tanker got damaged a fast on-site solution was needed to restore the propeller’s balance with a minimal loss of efficiency. This would avoid an extended off-hire period to go to drydock.

One of our teams was therefore rapidly mobilized to the ship’s location in Singapore. Here they met up with our local support base. They assisted us during the operation.

The expertise and experience of our divers allowed them to easily divide the repair in parts so that the propeller modifications could be performed in the shortest possible time frame.

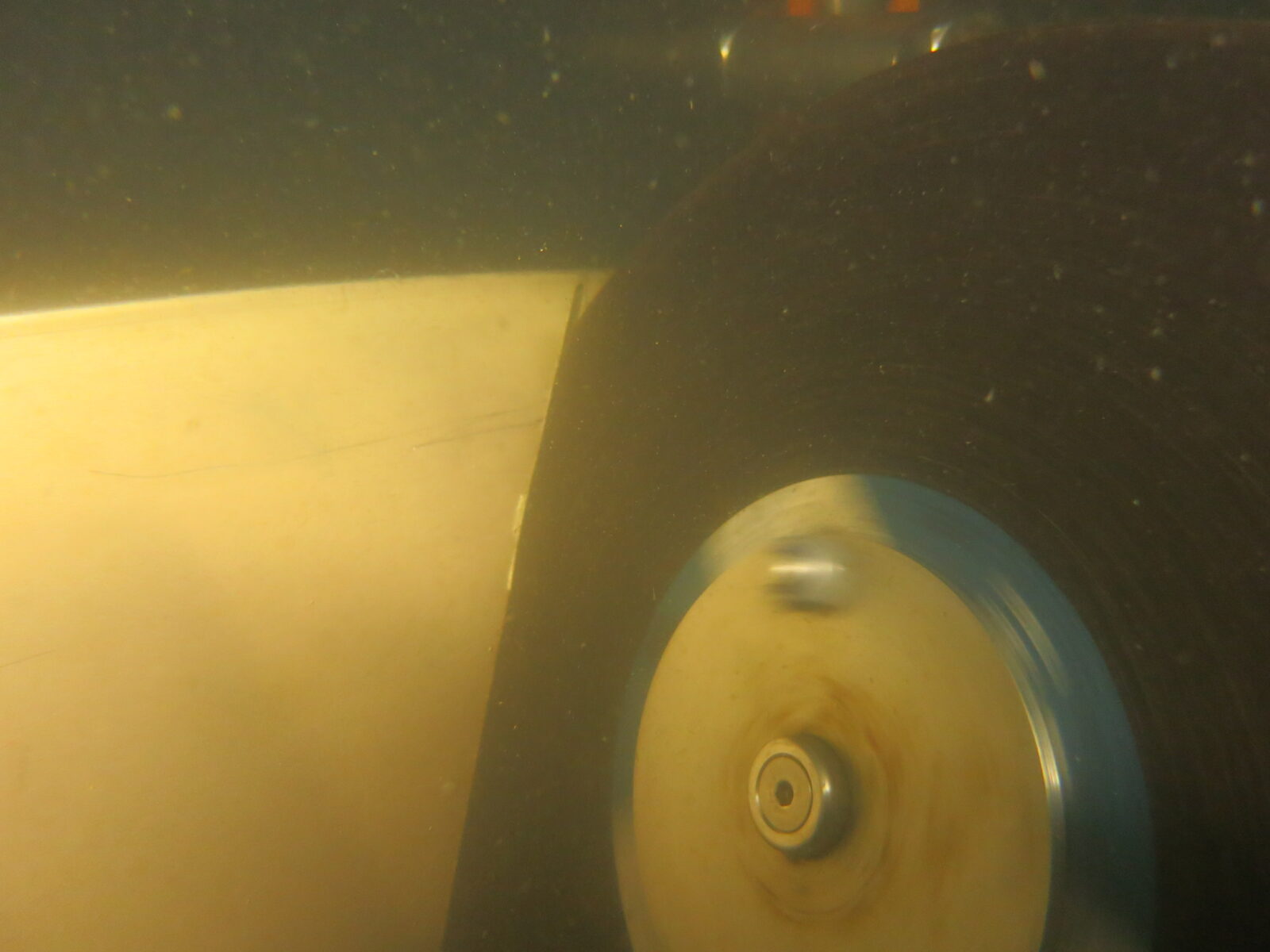

After the team arrived at the vessel’s location they started the underwater operation with a detailed survey of the affected propeller blades. This underwater inspection revealed that one of the four blades was bent 90°. Cropping was unfortunately the only option.

This kind of repair is carried out with the propeller blade cutting equipment developed by our research department. The equipment is lightweight and can be mobilized together with the divers.

The team used the information acquired during the inspection to calculate and determine the ideal cutting line. They then cropped the damaged blade and ground the edges to give it the correct shape. The opposite blade had only been slightly damaged, but it was also cropped to keep the propeller’s balance. This blade had suffered smaller cracks and dents along its trailing edge. Our divers therefore grinded out the cracks and polished the edge of the blade. This gave the propeller back its original efficiency and prevented further cracking.

When the cropping was complete our men polished the two cropped blades to make sure that any remaining loss of efficiency would be minimal. The other two blades needed no modifications.

During the operation a class surveyor was present. He gave his approval for the repair after a final inspection.

Conclusion

Damaged propeller blades will have a performance below average and cause vibrations. The engine will have a higher work load. This results in increased fuel consumption and added stress. If straightening is not an option, the affected area on the blade will be cropped. By doing this the greatest possible efficiency is achieved for the vessel. This type of repairs can be performed on-site and underwater, allowing a ship to continue commercial operations without the need to drydock.

Contact us for more information on underwater propeller repairs. We are at your disposal 24/7.