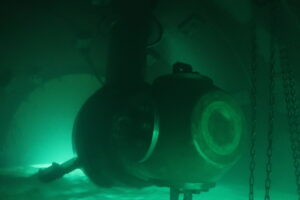

Recently one of our diver/technician teams performed a successful propeller blade cropping operation on a 175-meter bulker while the vessel was in Klaipeda, Lithuania. Because of the severity of the damage, cropping was the only option.

When the propeller blades of the bulker were damaged as a result of impact with ice, a fast on-site solution was needed to restore the propeller’s balance with a minimal loss of efficiency. This would avoid an extended off-hire period to go to drydock.

One of our teams was therefore rapidly mobilized to the ship’s location in Lithuania. After they arrived at the vessel’s location they started the operation with a detailed survey of the affected propeller blades. Because the ship could be trimmed by the bow, the entire operation could be performed above water.

The inspection revealed that three blades were bent over an angle of 90°, one blade was bent slightly less while that last one was bent even further. Cropping was unfortunately the only option.

This kind of repair is carried out with the propeller blade cutting equipment developed by our research department. The equipment is lightweight and can be mobilized together with the divers.

The team used the information acquired during the inspection to calculate and determine the ideal cutting lines. They then cropped the damaged blades and ground the edges to give them the correct shape.

When the cropping was complete, the blades were polished to make sure that any remaining loss of efficiency would be minimal.

During the operation a class surveyor was present. He gave his approval on the repair after a final inspection.

Conclusion

Damaged propeller blades will have a reduced performance and cause vibrations. The engine will have a higher workload. This results in increased fuel consumption and added stress. If straightening is not an option because the bend is too severe, the affected area of the blade will be cropped. By doing this the greatest possible efficiency is achieved for the vessel. This type of repair can be performed on-site and above or below water, allowing a ship to continue commercial operations without the need to drydock.

If you have any questions regarding a possible propeller repair, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more propeller repairs and other case studies.

Underwater propeller blade replacement in Tasmania

Underwater bow thruster operation in Algeciras

Scrubber overboard pipe repairs in the Netherlands, France and Spain

Propeller blade cropping in Ghent avoids costly drydocking

Leaking seal assembly fixed underwater in Antwerp