Earlier this year our diver/technician teams carried out a double underwater stern tube seal repair on a roro ship berthed in Port of Burnie, Tasmania. The ship was leaking oil, making an on-site repair necessary. Using two Hydrex flexible mobdocks simultaneously the team was able to carry out the entire operation on-site and underwater, saving the owner an expensive and time-consuming trip to drydock.

After arriving on-site, the diving team first set up a monitoring station next to the vessel. The operation then started with a thorough underwater inspection of the stern tube seal assemblies.

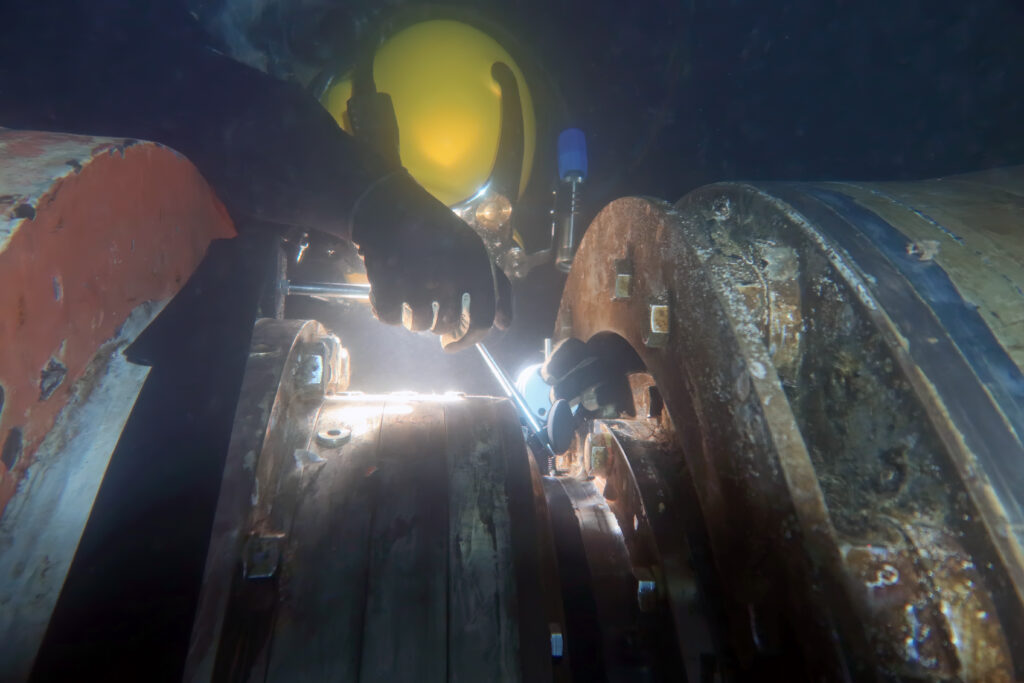

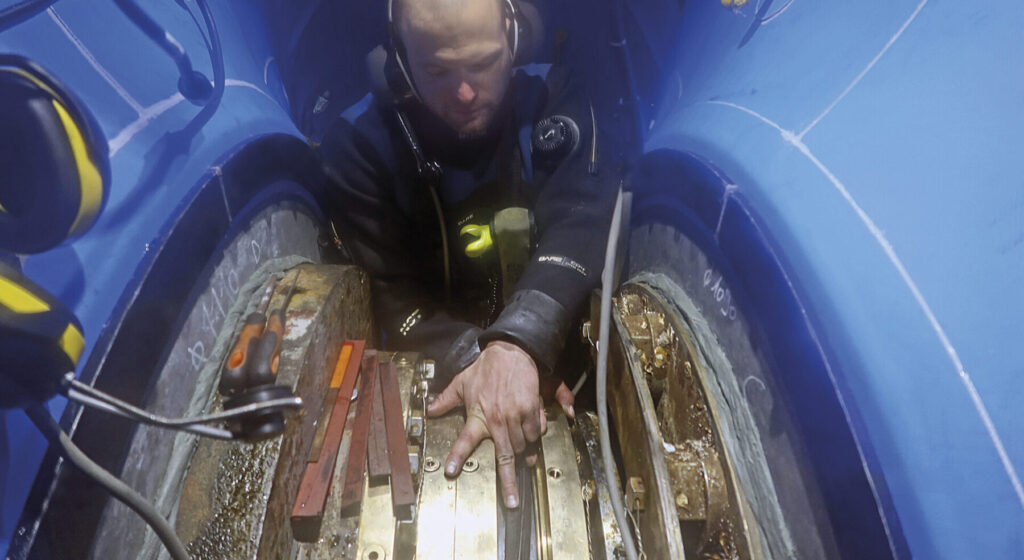

After the inspection the divers cleaned the assemblies and installed both flexible mobdocks. By doing this they created a dry underwater environment so that they could work in drydock-like conditions.

The exact same procedure was followed on both stern tube seal assemblies. The split ring was first disconnected and brought to the surface to be cleaned. After cleaning the entire assembly, the divers removed the first seal and replaced it with a new one which was then bonded. This was done in cooperation with the supervising OEM technician. The procedure was repeated with the other three seals.

A successful operation was concluded with leakage tests, the removal of the flexible mobdocks and the reinstallation of the rope guards.

Long distance a stimulus, not a hindrance

Despite the remote location of the roro vessel, our technical department was able to make all practical logistic arrangements and organize a mobilization of the equipment very swiftly. In the recent past we have carried out several operations in Australia. On several occasions we mobilized to the same location for an identical job on this ship and its sister vessel, so the customer knew we could perform the operation fast, safely and to the highest quality standards.

Taking advantage of flexible mobdocks and years of experience our men carried out the repair while the ship stayed afloat. Because all the required material is ready to be transported at all times, no time is lost making preparations.

With Hydrex organizing everything from start to finish, the owner did not have to worry about making any arrangements for the repair. After the seals had been successfully replaced, he could sail his vessel to its next stop free of oil leaks.

If ever you need assistance with the underwater part of your vessel, give us a call. We can then tell you if the repair is feasible and start working on its handling.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more case studies.

Underwater repair of leaking seal assembly in Trinidad

Underwater bow thruster removal and reinstallation in Australia

Scrubber overboard pipe repairs in Belgium and the Netherlands

Insert installation in Uruguay prevents loss of contract

Double stern tube seal repair on second vessel in Tasmania confirms customer’s trust