Home - Press

Press

On this page you can find articles about Hydrex published on websites and in trade magazines.

New partnership between GAC Oman and Hydrex NV

Gulf Agency Company (GAC) Oman and Hydrex NV have signed an agreement to work together to add high quality underwater maintenance and repair to GAC Oman’s large portfolio of services.

Propeller cone fine installations save 3-5% in fuel consumption

Seal repair on pipelay-ing vessel in Rotterdam.

Hydrex replaced the seals of both stern tube assemblies of a pipe-laying vessel in Rotterdam. Using a Hydrex flexible mobdock the team was able to carry out the operation on-site and underwater.

Hull repairs across Europe

Over the last few months Hydrex has travelled across Europe to perform hull repairs on a wide range of

vessels, including a cruise ship, a container vessel, a drill ship, a ro/ro vessel and a tanker.

Scrubber overboard pipe repairs in Europe

Operations in Belgium and the Netherlands

The Hydrex headquarters is located in Antwerp and Rotterdam. The company’s fully equipped workboats allow them to mobilize immediately to operations in all ports in Belgium and the Netherlands.

Underwater stern tube seal repair in Tasmania

At the end of last year one of the Hydrex diver/technician teams carried out an underwater stern tube seal repair on a roro ship berthed in Port of Burnie, Tasmania

Dredging & Port Construction Sep. 2019

Horrified by the levels of pollution and sediment

contamination he saw when he started work as a

commercial diver, Boud Van Rompay founded Hydrex in

1974 with the goal of clean rivers, seas, and oceans.

Hydrex: Stern Tube Seal Repairs

Recently Hydrex carried out six stern tube seal operations all across Europe in a very short time span. Here is a review of two of the repairs. Both repairs were carried out in cooperation with the OEM.

SORJ August/September 2018

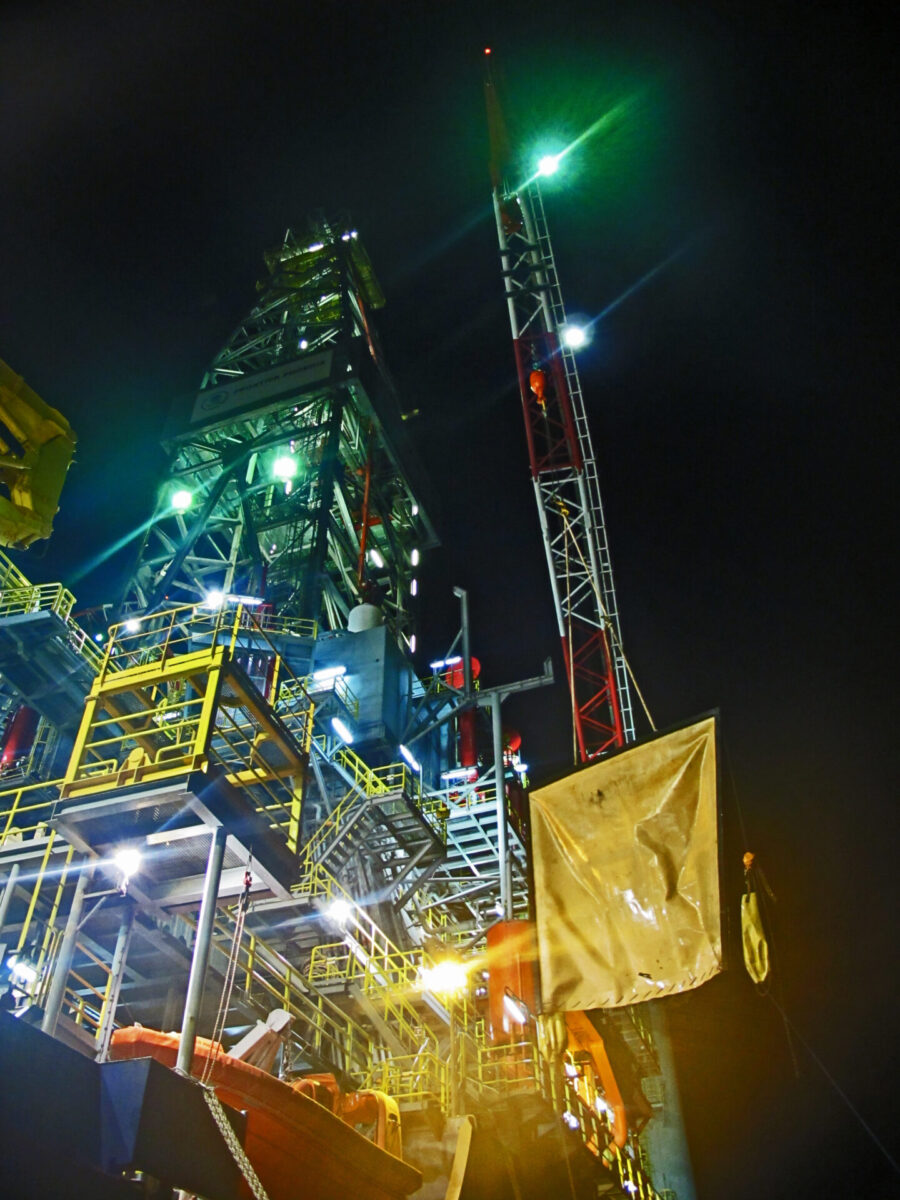

The transit flap of a 225-meter drill ship came loose and started swinging dangerously. This caused damage in the aft bulkhead and a leak in the ballast tank situated behind the moonpool hull.

Scrubbers leading to increased repairs

Hydrex said its technicians had recently carried out pipe replacements on 270m shuttle tankers where water that had scrubbed the exhaust gases corroded the pipework leading to water ingress.

Maritime Executive Sep/Oct 2017

Boud Van Rompay, Founder & CEO, Hydrex and Subsea Industries. Diver, entrepeneur, inventor, author, Van Rompay sets the bar high. His goal? Clean rivers, seans and oceans.

Shiprepair & mainte-nance 1st Quarter 2017

The introduction of a new design of underwater habitat for

rudder repairs can save shipowners thousands of dollars

in emergency drydocking costs, according to Hydrex

Underwater Technologies.

Propeller repairs incr-ease as winter comes

Hydrex has registered an increase in the number of vessels experiencing propeller damage. While winter months usually result in an increase, this normally occurs between January and March.

The complete underwater package

For 40 years Hydrex has pioneered many new underwater maintenance and repair technologies. We have always found ways to solve the problems our customers are faced with.

Marine News August 2016 MN100

Hydrex offers turnkey underwater repair solutions to shipowners wherever and whenever they are needed. Hydrex’s multidisciplinary team will help you find the best solution

Seatrade Cruise Review June 2016

Hydrex underwater technology has been carrying out repairs on cruise ship azipod thrusters around the world. Owing to tight schedules, the window for such operations is very small.

Ship Repair Newsletter No 1600

A 175m tanker suffered cavitation damage to the inside shell plating of one of its ballast tanks. Hydrex mobilized a team to Algeciras to perform a permanent insert repair.

Underwater Rudder Repair in Rotterdam

In the beginning of December a Hydrex diving team mobilized to a 170-meter container vessel with one of our workboats. The team installed a doubler plate over the cavitated area of the rudder.

Permanent collision damage repair in Greece

In July Hydrex mobilized a team to Syros, Greece, for a complex repair operation on a 118-meter, 8550 DWT chemical tanker. The vessel had suffered large cracks in her hull plating as the result of a collision.

Underwater Rudder Crack Repair in Haifa

A Hydrex team traveled to Haifa, Israel to carry out a crack repair on the rudder of a 260-meter container vessel. The divers started the operation with an underwater inspection of the affected area.

Hydrex keeps vessels out of drydock

Belgian underwater service company, Hydrex, has successfully completed insert repairs on two vessels in Zeebrugge and Antwerp while all commercial activities continued without disruption.

Hydrex Reinstalls Thruster Seals

Emergency Rudder Repair in Scotland

Hydrex mobilized a diver/technician team to carry out the rudder repair in Ullapool, Scotland. Shortly after a 101-meter ferry left drydock, its rudder started showing wrong readings.

Hydrex work together with Wärtsilä

A sealreplacement was carried out in close cooperation with the Seals and Bearings Services division of Wärtsilä Netherlands B.V. The owner could sail his vessel free of water ingress without drydocking.

Dry Cargo International October 2013

Hydrex offers underwater repair and maintenance solutions to shipowners. The company helps its clients find the best solution for any problem encountered with their ships below the water line.

Tug & OSV May/June 2013

A Hydrex diver and technician team, utilising the company’s new workboats obtained in December last year, removed the bow thruster of a 300m container vessel in Rotterdam.

Azimuth thruster replacement on Crane Barge

On several occasions Hydrex teams have mobilized to an offshore crane barge stationed at its service base in Gabon to replace one of the vessel’s swing-up azimuth thrusters with a spare.

Shiprepair & Conversion Technology

In a period of only 10 days Hydrex diver-technician teams recently flew

across the globe to perform a wide range of underwater operations on five

different continents.

Ship & offshore June 2012

A ship's propeller represents only a ver small fraction of the vessel's wetted surface area. Yet the effects of a rough propeller on the vessel's fuel consumption are large.

Marine Engineers Review April 2012

Around the world the Belgian specialist Hydrex has carried out repairs and replacements on all types of seals in-situ, and in most cases underwater, for a number of years.

Marine Propulsion February/March 2012

Hydrex markets solutions that enable stern tube seal work to be carried out without having to drydock. In a recent example, a sterntube oil leak had devel-oped on a cargo vessel located in Mobile.

Marine Maintenance Launch issue

Save the day: The insertion of a complete, prefabricated replacement hull section in a badly damaged ship at anchor is believed to be a world-first in underwater repair.

Daily collection of maritime press clippings 2024– 185

On May 16th, 1974, Hydrex was officially born. In the 50 years since then the company has grown from a small diving firm operating from a home office...

Underwater Work in Singapore

Hydrex has been performing underwater maintenance and repair operations in Singapore for 40 years.

Drydock Magazine – Issue: January – March 2023

Underwater tanker repairs in Flushing

Hydrex helps vessels steer clear of trouble

Hydrex has carried out several rudder repairs on ships in Belgium and France. In all cases cracks were found that needed to be repaired to prevent them from spreading and causing further damage.

Emergency hull repair on ferry Texelstroom

The vertical side of the ferry Texelstroom was damaged during storm Eunice. A leak in the ballast water tank prevented the ship from sailing. This happened at the start of a busy school vacation period.

Scrubber repairs in France, Spain and Malta

Recently Hydrex carried out scrubber overboard pipe repairs in ports in Belgium, France, Malta and Spain. On a container ship two pipes were replaced while one pipe was replaced on a tanker.

Underwater repairs keep vessels trading

While propulsion system and propeller maintenance work is often carried out ashore, specialist underwater repair companies have a key role to play in this particular sector.

Hydrex repairs in winter conditions

In just over a week Hydrex diver/technicians travelled to Finland, Germany, the Netherlands and France to assist shipowners with damaged propeller blades.

Underwater insert repair in Rotterdam

A chemical tanker suffered erosion damage in the grey water tank. Hydrex was contacted by the owner to provide an underwater solution that would allow the vessel to keep her schedule.

Underwater Thruster Removal in Rotterdam

Last month a Hydrex team removed a bow thruster from a 170-meter container ship during a stop in Rotterdam. The operation had to be carried out within a very short timeframe.

Underwater stern tube seal repair in Tasmania

ydrex diver/technician teams carried out an underwater stern tube seal repair on a roro ship berthed in Port of Burnie, Tasmania. The ship was suffering from an oil leak.

Approval for propeller cleaning method

In close communication with the Dutch Ministry of Infrastructure and Water Management, Hydrex has developed a new method to clean propeller blades underwater.

Time is of the essence in bow thruster removal

Tight schedule that time is a critical factor in almost all repair jobs. This is particularly true for those conducted underwater, where the possibility of water ingress presents an extra challenge.

Underwater Shaft Seal Repairs in Record Time

Hydrex has developed a flexible mobdock repair method that enables the underwater replacement of all types and sizes of shaft seals. It allows ship owners to keep their vessel sailing

Shiprepair & Mainte-nance 4th Quarter 2017

Hydrex’s underwater repairs keep vessels

on schedule. Mobdock repairs demand speed and efficciency, as the Belgian company demonstrated with a recent cruiseship thruster refit.

Ship Repair Newsletter No 1681

Last month saw a flurry of activity for Hydrex dive teams, with a number of hull repair and shel plate projects in Europe and the United States. All repair projects were carried out afloat.

Marine Engineers Messenger, Issue 27

Keeping dry when the outlook is wet: Hydrex Underwater Technologies’ next generation Mobdock and cofferdam designs are changing the way in which thrusters are removed and repaired.

Marine Maintenance October 2016

Stern tube seals and thrusters. Below the surface : Flexible underwater habitats are opening up a wide range of less costly in-service repair and maintenance options for operators.

Drydock Magazine September 2016

Recently a team of Hydrex divers performed a propeller blade cropping on a 190m container bulker berthed in Hamburg. Two parts of the tip of one of the four propeller blades were damaged.

Ship Repair Newsletter No 1621

Recently, a team of Hydrex divers performed a propeller blade cropping on a 190 m container/bulk carrier berthed in Hamburg. Two parts of the tip of one of the four propeller blades were damaged.

Seal renewal in tough underwater conditions

In April a Hydrex diver/technician team carried out underwater stern tube seal repairs on a container vessel in Tauranga, New Zealand. The ship was suffering from an oil leak.

Underwater Contractor International Jan/feb 16

In December 2015 a diving team from Hydrex, Belgium, mobilised to a 170-metre container vessel with one of its workboats. The team installed

a doubler plate over the cavitated area of the rudder.

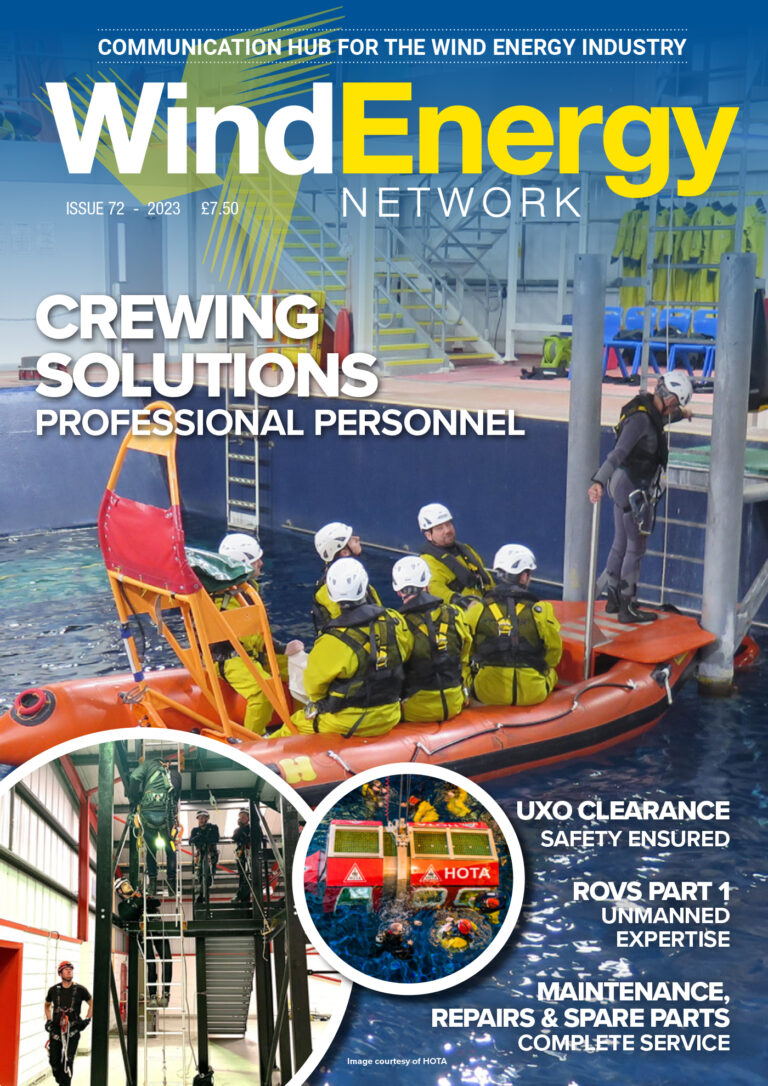

Shipbillding Industry Issue 6, 2015

Hydrex offers turneky underwater repair and maintenance solutions to shipowners wherever and whenever they are needed. They have a large and multidisciplinary team.

Hydrex Fixes Stern Tube Seal in Australia

Hydrex carried out underwater stern tube seal repairs on a 200-meter roro vessel in Port Kembla, Australia.The ship was suffering from an oil leak, making an on-site repair necessary.

Shiprepair and Conver-sion Technology 2015

Propeller maintenance: New techniques meet need for speed. Diver-technicians from Belgium-based Hydrex have recently carried out a variety of work to tight time scales.

Hull repairs: no drydock required

Hydrex offers fast on-site vessel repairs in emergency situations. Unlike many, however, they can perform the cost saving feat of repairs below the waterline with the vessel still afloat.

Hydrex Performs Dredger Underwater Repairs

Hydrex carried out underwater stern tube seal repairs on a 157-meter dredger in Montevideo, Uruguay. The ship was suffering from an oil leak, making an onsite repair necessary.

Pile Buck 2014 Volume 30 Issue 2

Last month a Hydrex carried out under-water stern tube seal repairs on a 110-meter offshore supply vessel in Bunbury, Australia. The rope guard covering the stern tube seal assembly was missing.

Hydrex Founder Speaks about Seal Repairs

Don't Forget the Diver: Avoid Drydock Repairs

Hydrex underwater repair solutions can be done wherever and whenever they are needed. Hydrex will immediately mobilize to carry out necessary repair work without the need to drydock.

SORJ February/March 2013

In recent months Hydrex has carried out bow thruster blade replacements on several occasions in Rotterdam. Three 366m container ships were given the same speedy treatment.

Doubler plate repair on bulker after collision

A bulker suffered severe collision damage in Lagos, Nigeria. The classification society demanded that the vessel go to drydock immediately unless an on-site solution was found.

Ship and offshore repair journal June/July 2012

World-wide activities at Hydrex. The services offered ranged from routine inspections and maintenance work all the way through to highly technical major repairs.

Propeller Blades Repaired Underwater

Shipping World & Shipbuilder March 2012

In-situ repairs of seals help owners extend their vessels’ drydock interval and eliminate loss of time and production. One company that has carved a niche in this particular business is Hydrex.

Tug & OSV January/February 2012

The complexity of coordinating and overseeing a major salvage

operation and bringing it to a successful conclusion under

demanding circumstances is no mean feat.

Thruster Replacement in Rotterdam

Hydrex completes mobile seal replacement

Hydrex mobilized to the Netherlands and Australia to carry out seal replacements. In Flushing the repair was carried out on a 200-meter car carrier, and in Port Burnie, Tasmania, on a 188-meter RoRo vessel.

Seachest insert repair in Rotterdam

A tanker suffered leakage in the starboard side seachest of its engine room. Hydrex was asked to provide an on-site solution and sent a team to the ship’s location in Rotterdam to carry out an insert repair.

Hydrex carries out more scrubber outlet repairs

Ready to Mobilize at Port of Rotterdam

To enable a fast mobilization throughout the entire Rotterdam port without delaying a ship’s commercials operations, Hydrex dive support vessels are stationed in Rotterdam.

Emergency grounding repair in Phuket

While a Hydrex diver/technician teams was performing an underwater bow thruster repair in Phuket, a cruise ship suffered grounding damage while on its way to this location.

Dry Cargo International November 2019

Hydrex teams recently carried

out several rudder repairs on ships in

Belgium and France. In all cases cracks

were found that needed to be repaired to

prevent them from spreading.

Underwater rudder operation in Dubai

Mobdock enables fast transducer installation

Belgian underwater repair specialist Hydrex recently utilised its mobile drydock system, mobdock, to facilitate the installation of an echo sounder and speed log system in just one day.

Modifying Propellers to Meet Requirements

Hydrex says it is carrying out more modifications to a ship’s underwater areas and equipment in addition to the company’s more common damage rectification work.

Ship & offshore October/November 2017

Ship & Offshore March 2017

A new and redesigned version

of Mobdock, first introduced to the market by Hydrex Underwater Technologies

in 2002, now enables permanent in-water

rudder repairs to be carried out

Hydrex Averts Panama Canal Delay

Hydrex Underwater Technology has assisted an excavation vessel hemorrhaging oil from a stern tube seal entangled with steel wire to pass safely through the Panama Canal.

Hydrex Repairs Stern Seal in Record Time

Hydrex has completed the emergency stern tube seal repair to a 134m chemical tanker, after the Antwerp Port Authority demanded an underwater inspection and in-situ repair to the vessel.

The Value of Underwa-ter Inspections

Building upon conventional technical skills and know-how while also taking advantage of the latest technology, Hydrex offers a unique hull monitoring service to its customers.

Quick Propeller Repair Prevents Drydocking

Recently a team of Hydrex divers performed a propeller blade cropping on a 190-meter container bulker berthed in Hamburg. Two parts of the tip of one of the four propeller blades were damaged.

Shiprepair and conversion technology

The Belgian underwater repair specialist, Hydrex, has undertaken work in

Europe, Australia and South America in recent months, drawing heavily on

technology developed by its research department

Daily Maritime Press Clippings 2016 - 033

In November a diver/technician team performed a successful propeller blade cropping operation on a 229-meter bulker under difficult weather circumstances while the vessel was in Punta Del Este.

Hull repair on drill ship in Gulf of Mexico

The transit flap of a 225-meter drill ship came loose and started swinging dangerously. This caused damage in the aft bulkhead and a leak in the ballast tank situated behind the moonpool hull.

Marine Propulsion February/March 2015

During 2014, for example, Hydrex replaced three leaking bow thruster shaft seals on a six-month-old 400m container ship in Gdansk, Poland, without causing any delay to the ship.

Underwater Thruster Installation on Schedule

Two and a half months after Hydrex removed the bow thruster of a 363-meter container vessel in Rotterdam, a Hydrex team once again mobilized to reinstall the overhauled unit underwater.

Collision damage repair at Neorion Shipyards

In July Hydrex mobilized a team to Syros, Greece, for a complex repair operation on a 118-meter, 8550 DWT chemical tanker. The vessel had suffered large cracks in her hull plating as the result of a collision.

Underwater blade replacement keeps schedule

In April, underwater repair company Hydrex carried out bow thruster blade replacements on a 270m container ship in Barcelona. This enabled the owner to have a condition of class removed.

Propeller Repairs in Extreme Conditions

When damage to propellers occurs due to impact with ice and other debris, Hydrex will help, even if the damage is quite ex-tensive. In Antwerp, Ventspils and Kiel Hydrex carried out underwater repairs.

Quick underwater seal repair in Port Gentil

In August, the stern tube seals of a 67-meter, 2223 grt anchor handling vessel were replaced in Port Gentil by a Hydrex team. The old seals were damaged and a fast repair was therefore necessary.

New mobdock used in Port Everglades

In February Hydrex diver/technician teams carried out underwater stern tube seal repairs on a 139-meter container vessel in Port Everglades, Florida, close to the company’s office in Clearwater.

Stern Tube Seal Repairs in US and Panama

Recently Hydrex diver/technician teams carried out two underwater stern tube seal repairs: one on a 143-meter general cargo ship in Galveston, Texas, and one on a 292-meter container vessel in Panama.

Turnkey Underwater Repair Solutions

Hydrex offers underwater repair solutions to offshore related units. Hydrex’s will help you find the best solution for any problem encountered with your vessel or offshore unit below the water line

Underwater Thruster Repair & Maintenance

An entire unit can be overhauled, propeller blades or seals can be replaced or repair work on a specific part of a thruster can be performed fast by Hydrex diver/technicians on site.

Welding Journal March 2012

Undertaking a complex underwater repair: A damaged freighter needed repairs to stop a leak, prevent buckling and keep cracks from spreading so the ship could sail to where she could unload.