Home - Core values - An enviable safety record

An enviable safety record

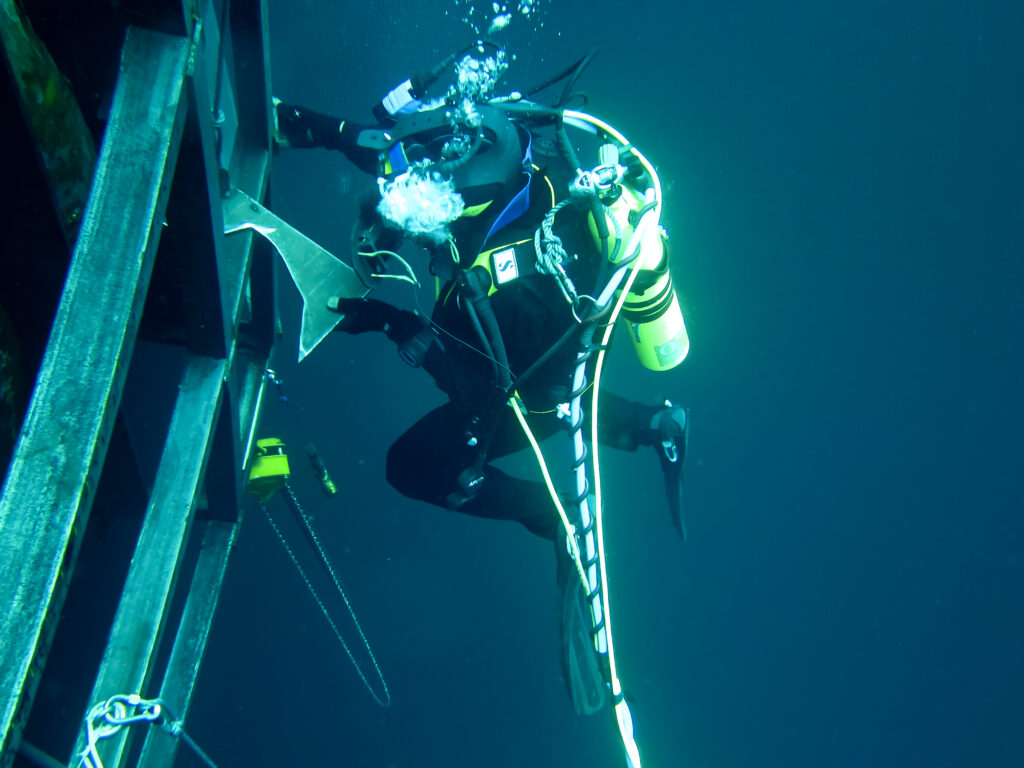

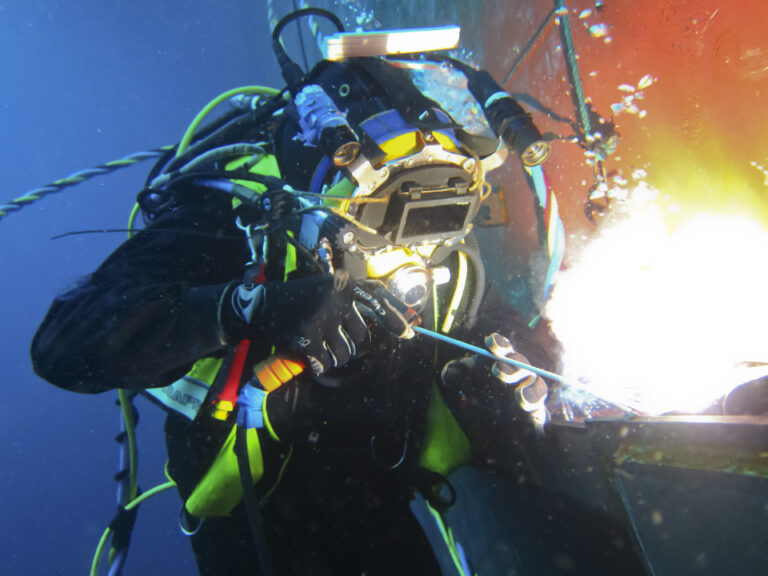

Hydrex has been delivering high quality underwater repair and maintenance services continuously since 1974. A great deal of work has been performed all over the world in all seasons and conditions, often by large teams of divers and technicians. In all that time there has not been one single serious accident. This is a remarkable record. How has this been possible and why is it so much part of Hydrex’s DNA?

Boud Van Rompay, Hydrex founder and CEO, came from a background of very successful cave diving, perhaps the most dangerous form of diving there is. He had survived more than his share of narrow escapes. But some of his close friends had not been so fortunate. The memory of seeing the parents of two friends after both had suffered fatal accidents in 1972 remains with him to this day. When it came to other people’s lives, Boud was determined not to take any risks.

“When I founded the company in 1974, my first action was to write a safety manual,” he recalls. “It covered all aspects of diving, commercial underwater work, how to manage divers, the size of the teams, what equipment to use, what to do, what not to do. When you’re dealing with a team or a group, you need sensible rules that everyone can study and apply, so that you have a common agreement.”

“Having and studying the rules and taking the whole job and the procedures seriously, prompts the individual in the team to become better and better with regard to safety,” Boud continues. “The result for us has been almost 50 years without a serious accident.”

Boud feels that if a company has a poor safety record, it comes from irresponsibility, lack of clear rules or lack of respect for the rules.

Companywide concern

At Hydrex, concern about safety runs through the entire company, not only with the divers.

Dave Bleyenberg was a Hydrex diver for eight years before becoming a Technical Services Officer responsible for arranging the jobs and overseeing their successful execution. “Comparing safety at Hydrex with other companies, we are at the highest level,” he says. He attributes this to a number of factors. Not cutting any corners on equipment is one. “If you look at our equipment, it’s new,” he says. “If we have any doubt, it will be replaced. When you go into a company’s depot and look at the shelves, you know immediately.”

Another key factor is the divers, individually and as a group. Obviously the divers have to be qualified, but there is more to it than that. “We have created a solid group here at Hydrex and the individual’s safety depends on this being maintained. You can have a good diver but if he doesn’t fit into the group here, it’s a risk to the group’s safety so we will not hire him.”

Safety always takes precedence over financial or commercial considerations. “We won’t take a risk because of commercial or time pressure,” says Dave. “That is firm policy.”

Personnel and equipment

Toon Joos, Chief Diver, has been with Hydrex for close to 20 years. In addition to acting as Team Leader on jobs, he is overall responsible for training the divers. “We have never had a major accident,” he says. “It’s down to selection, training and experience and the attitude of the divers who are willing to work safely.”

“Having state-of-the-art, well-maintained equipment is also very important,” says Toon. It is a point of pride for Hydrex.

Koen Smouts, Technical Preparation Officer, is in charge of the depot and purchasing and maintaining all Hydrex’s equipment including workboats, trucks and vehicles as well as diving gear. Everything is in its place, operational, clean and ready to deploy. His sense of order and his a care for the equipment strikes you immediately when you walk into the Hydrex Antwerp depot. “Part of my work every day is training the divers on the equipment, how to care for it and maintain it, how to work together as a team to repair something on site if it is broken,” says Koen. “When I train them, I also always tell them why it needs to be a certain way.” This all contributes majorly to the company’s safety record.

Clément Pâquet, Lead Diver is another veteran who has been diving for Hydrex for almost as long as Toon Joos. “I have always felt safe as a diver here,” he says. “We try to keep the situation under control always, not leave things up to other people. When you have things in hand yourself, you can be sure it’s going to turn out properly. We have a discipline. If you know what you are doing, you can eliminate the risks. This comes mostly from experience.” On any job he goes on, Clément usually has the role of Team Leader. He goes on board to meet with the Chief Engineer and Chief Officer and ensure that safety measures are in place on the ship and that no one is going to turn the bow thruster on accidentally when they’re working in the thruster tunnel, for example. Then he holds a short meeting with the entire team and makes sure everyone knows what they will be doing.

The attitude of management is important. “Management doesn’t push us, so we always have the time to do things safely and correctly,” says Clément. “It’s not always easy, because sometimes we are working on a tight schedule, but if something is not safe, we do not start.”

Henri Allard is a First Diver who came to Hydrex in 2016 after working at another dive company. “I feel very safe as a diver here,” he says. “Everybody is concerned about maintaining the dive helmets and equipment in general, doing checks and yearly maintenance. If something is broken it gets reported immediately. I also feel safe as far as the other team members are concerned. Except for the student divers, I can rely on everybody. And the student divers just need to learn – they rely on me.” Henri makes sure that the divers he is responsible for are properly equipped and that procedures are followed. “That’s my responsibility as First Diver,” he says.

“I hear from freelancer divers that Hydrex is one of the safest companies to work for,” adds Henri. “We are known for having the best equipment and that Hydrex is safety-conscious and efficient.”

Manuel Hof is in charge of quality control and compliance at Hydrex. “We have a Safety Assurance System,” he says. “This includes VCA external certification which is local to Belgium and the Netherlands. We also have our own diving standards and procedures. The maintenance of diving gear is really strict. The main point is to avoid accidents, not wait until there is a problem and then see how we can solve it.”

In addition to the lengthy list of requirements, on-board safety measures, training of the divers, pre-dive checks and equipment maintenance checks, Manuel explains, “It’s really important that management, team leaders and the person responsible for the depot, really encourage the divers to work in a safe way. If they don’t set the example, then the other divers will not follow the rules as, apparently it’s not that important.”

Team effort

One of the main reasons for Hydrex’s enviable safety record is the attitude that pervades the group from top to bottom that safety is a chief concern. Another important factor is the willingness to work together to follow the rules that have been developed from experience over the years.

If you have any questions regarding our underwater services, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

News and projects

Shell plating repairs in Belgium, the Netherlands and Trinidad

Over the last few months our teams traveled across the ocean to Port of Spain, Trinidad and just around the

Double stern tube seal repair on roro vessel in Tasmania

Earlier this year our diver/technician teams carried out a double underwater stern tube seal repair on a roro ship berthed

50 years of keeping ships in business

On May 16th, 1974, Hydrex was officially born. In the 50 years since then we have grown from a small