Home - Core values - Small jobs matter to us

Small jobs matter to us

We tend to publicize the more major underwater operations we do: stern tube seal repairs; thruster repair or replacement; propeller cropping and straightening; hull repairs. They are often quite heroic, requiring larger teams and special equipment. But on a daily basis we are also undertaking the smaller ship husbandry jobs that are just as important to the continued safe and efficient running of the ship. They all receive the same level of care and professionalism.

What are these maintenance jobs? Here is a brief outline.

Inspections

We perform several different kinds of inspections. Some require the presence of a class inspector. Others do not.

Quite often we are asked to carry out a general hull inspection and report on fouling and any damage. This does not require class presence.

Where class is definitely involved and directs the activities is the underwater inspection in lieu of drydocking (UWILD). This is videoed and the class inspector oversees the diver’s progress from the dive control center on our workboat or the quayside.

We also carry out inspections where a ship has grounded or touched the quayside and needs to be checked. There are also presale inspections where a ship is being sold. These can be requested by buyer or seller, and class is usually present to witness the inspection.

Sometimes a paint inspection is required. This is usually when the shipowner or operator feels that the antifouling coating is not working as advertised or that the ship is losing paint. This can often be a warranty issue, so careful photo and video documentation of the state of the paint on the hull is required.

“A well-conducted inspection, thoroughly documented with high quality photos and video can save an owner or charterer a great deal of expense and trouble,” explains the person in charge of Technical Estimations at Hydrex. With many years of experience as a diver, he is well qualified to provide accurate estimates as well as practical guidance to the customer. “We follow definite procedures and train our divers so that they conduct thorough and useful inspections,” he adds.

Propeller polishing

Regular propeller polishing represents considerable fuel savings for a ship. Figures of 5% or more have been estimated. Fuel costs and CO2 emissions can be reduced by this simple, straightforward and inexpensive measure carried out regularly with the ship afloat rather than waiting for the next drydocking.

Sea chest cleaning

When the grating of the sea chest has become blocked with hard fouling, it is time to have it cleaned. A tanker usually has many more gratings than a bulker for example and therefore it is a bigger job. But the fact remains for any ship: the sea chests must not become blocked as it will interfere with vital cooling.

Speed log and depth sounder transducer replacements

A ship’s navigation and its safety depend on knowing speed and depth at any time. The echosounder and speed log are vital instruments which must be maintained in good working order. If a transducer fails or begins to malfunction, it must be replaced. This requires work on the outside of the hull. Emergency drydocking is inconvenient and quite unnecessary for this purpose as the job can easily be handled by competent divers. The replacement is usually handled by blanking the opening in the case of the speed log, or removing and replacing the transducer from the outside in the case of the echosounder.

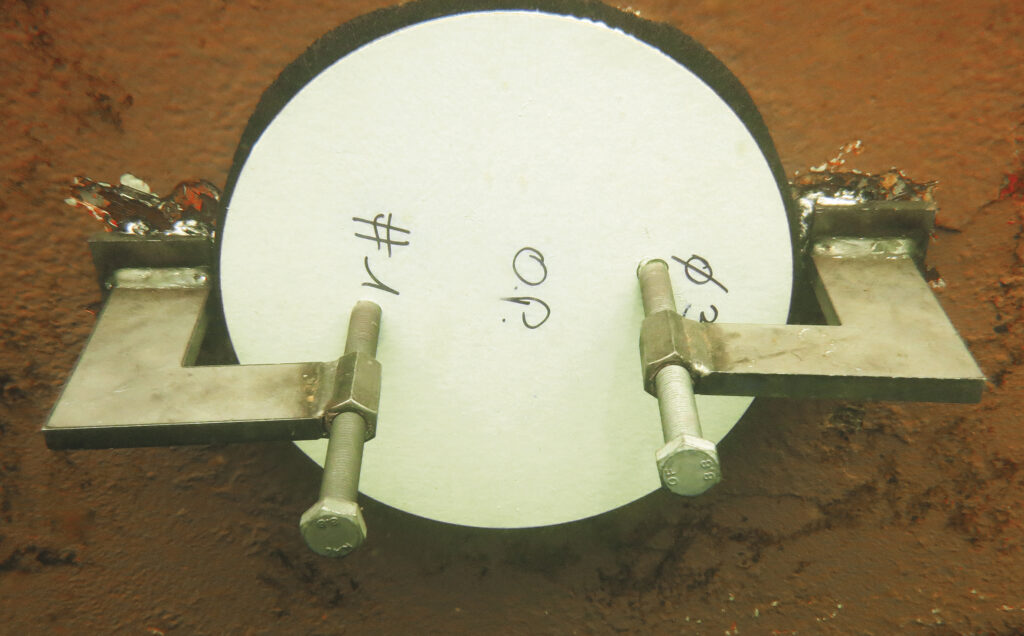

Blanking or plugging

When a valve inside the ship needs to be repaired or replaced, the opening must be blanked or plugged so that the operation can be carried out without taking in water. Usually the opening is blanked but with smaller openings it is sometimes practical to plug them while the work is carried out.

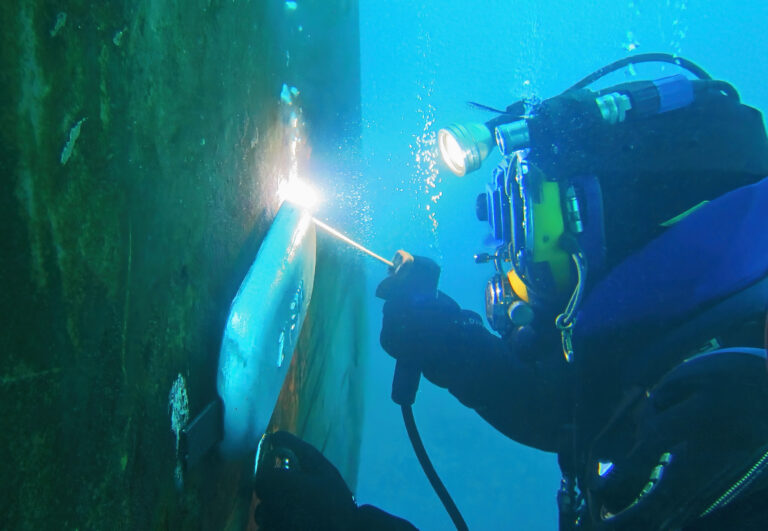

Anode replacement and ICCP renewal

Anodes wear down or can be damaged or can fall off and we are often asked to replace them. This is simply a matter of welding the new anodes in place. ICCP units also need maintenance and in some cases replacement. This can be done with the ship afloat rather than waiting for drydocking.

Unentanglement

Sometimes we are asked to come and clear a rope or net that has become tangled and caught up in the rope guard or rudder or propeller. Of course if we observe something of this nature while doing an inspection or a different job we will simply take care of it without additional charge, even if it wasn’t part of the original plan.

What do these jobs require?

The minimum team sent to carry out any of the above jobs is three diver/technicians. Regulations in some countries, such as Spain, require a minimum of five divers. If the job is likely to require our presence inside the ship as well as in the water, as can be the case with transducer replacements or valve repair, we send a team of four or five. This is also the case when the job must be carried out at great depth, since the time a diver can work at those depths is limited. A larger team can get the job done more quickly which is often important so that the ship can stay on schedule.

Timo Verhoegstraete, Technical Services Officer for Hydrex, whose function it is to take care of the logistics and personnel for jobs once they have been confirmed, says, “Our aim is to send out the minimum team needed to get the job done in the required time while meeting the constraints of local diving regulations and conditions. We always take into account the economics of the job for the customer to make it as cost-effective as possible.”

As always, the team that we send out consists of well trained and experienced divers and technicians capable of thinking on their feet and handling anything that comes up.

Logistics and equipment for smaller, maintenance jobs of this nature are handled exactly the same as for a major operation. No shortcuts are taken.

Combining jobs

Sometimes two or more of these maintenance jobs can be combined. For example, an inspection and a propeller polishing can be carried out in the same visit by the same team. This represents considerable savings to the shipowner or operator, since the cost of mobilization and transport is often a large part of the overall cost of a job.

Sometimes an inspection reveals a problem that needs immediate attention. Such repair can be begun immediately with the same team once the project has been approved by the customer. A grounding inspection may find damage that needs immediate repair. It can save costs to have the team that is already on site shift gears from inspection to repair, rather than sending out a whole new team.

“Since our experienced divers and technicians are all trained on all the procedures, the same team can take care of crack repairs, rudder repairs, propeller straightening and cropping and anything else that comes up,” says Toon Joos, Chief Diver, who is overall in charge of Hydrex technical activities and training of divers.

Additional equipment may be needed but it is more cost-effective to rapidly ship the equipment than to demobilize and remobilize a whole team.

We operate entirely from the viewpoint that we are here to take care of all the maintenance and repair your ships need while keeping them out of drydock and on schedule. So we put the same care and professionalism into a minor inspection as we do for a double stern tube seal repair.

If you have any questions regarding our underwater services, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

News and projects

Shell plating repairs in Belgium, the Netherlands and Trinidad

Over the last few months our teams traveled across the ocean to Port of Spain, Trinidad and just around the

Double stern tube seal repair on roro vessel in Tasmania

Earlier this year our diver/technician teams carried out a double underwater stern tube seal repair on a roro ship berthed

50 years of keeping ships in business

On May 16th, 1974, Hydrex was officially born. In the 50 years since then we have grown from a small