A 184-meter, 50.885 DWT chemical tanker had hit a buoy. A full underwater inspection and repair was needed. The vessel was only launched last year and was on a long drydock interval. Coming in for repairs now would have been a financial disaster for the owner. We therefore immediately mobilized an emergency team to Dubai to perform the inspection and any required follow up repair afloat.

After the equipment arrived at the vessel’s location the team started the operation with a detailed survey of the underwater ship. Fortunately this revealed that only a single blade of the propeller had been damaged. Because the damage to the blade was minimal only a small part of the blade needed to be cropped.

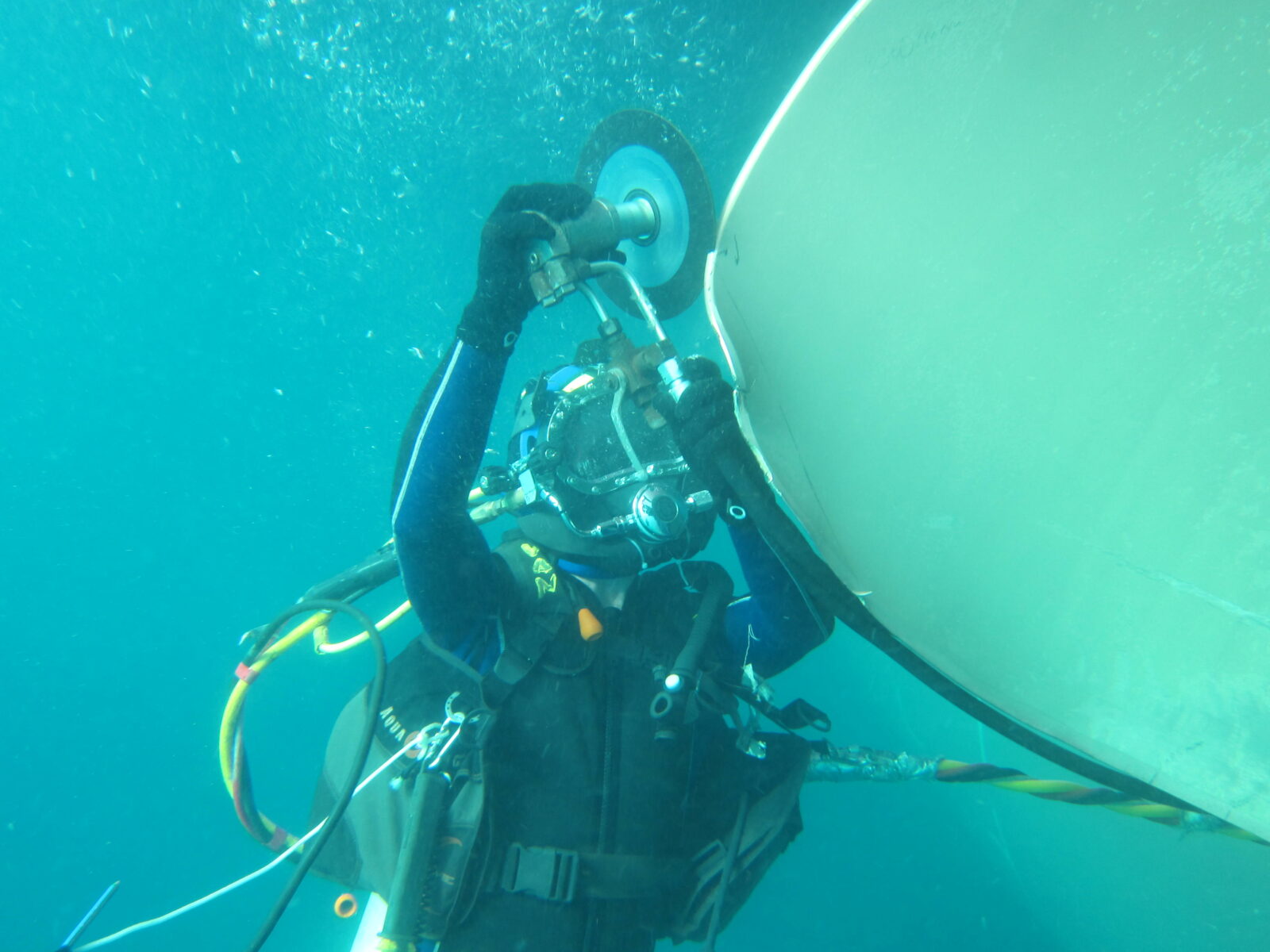

The team used the information acquired during the inspection to calculate and determine the correct measurements needed to modify the tip of the propeller blade. The repair proposal was then discussed with the class and the owner. After it was approved, the divers cropped the blade and ground its edge to give it the correct radius and shape. Some small nicks and cracks along the trailing edge were also repaired. When the cropping was complete, the Hydrex technicians polished the blade to make sure that any remaining loss of efficiency would be minimal. No rebalancing of the propeller would be needed in this case as the part of the blade that was removed was within the acceptable range.

The operation took less than a day. Thanks to the emergency repair the ship could keep its schedule instead of having to go off-hire. No further actions will be needed until the vessel docks in four years.