The transit flap of a 225-meter drill ship came loose and started swinging dangerously. This caused damage in the aft bulkhead and a leak in the ballast tank situated behind the moonpool hull. The vessel was located in Trinidad but was about to start a contract in Grand Isles, Gulf of Mexico. A fast solution was needed to prevent further damage and allow the ship to arrive in Grand Isles on time.

Hydrex mobilized a team of diver/technicians to Trinidad. After an inspection of the damage, they disconnected the transit flap. It was then lowered to the ocean bottom and towed away. In Trinidad the divers also took all the measurements needed to design a repair plan for the second phase. Because of the instable condition of the flap, it was essential to keep to the highest safety standards, especially during this first part of the operation.

The drill ship then sailed to the Gulf of Mexico. The limited time frame did not allow for a permanent repair to be carried out at that point, so a temporary solution was proposed and accepted.

The vessel once again met up with a Hydrex team. All the equipment was put on board the vessel before it sailed on to Grand Isles to start its contract.

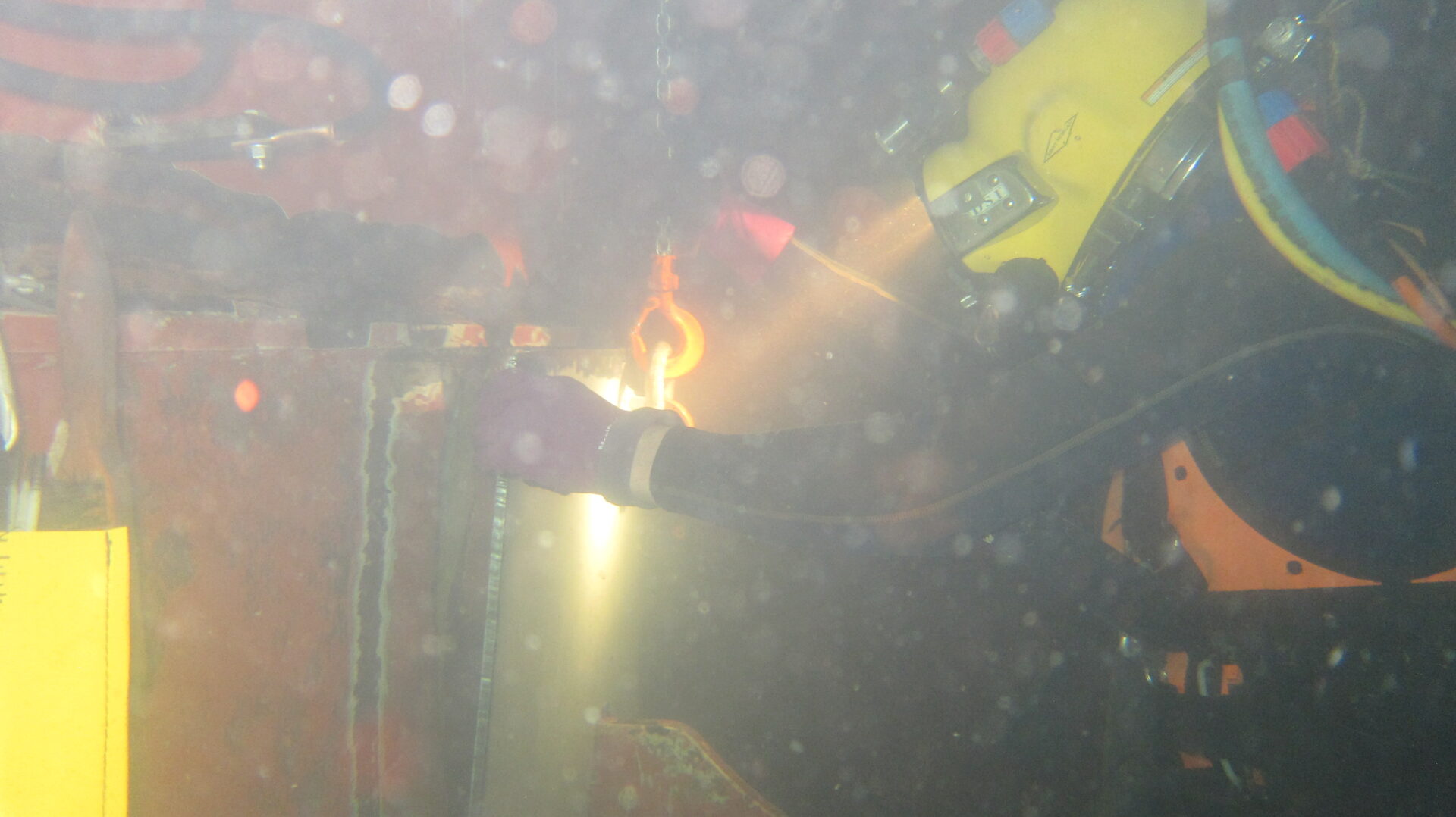

This part of the operation consisted of the installation of five doubler plates over the damaged areas in the aft bulkhead. Constructed with the exact measurements taken during a detailed inspection, they were positioned and secured underwater by our certified diver/welders. All water was then emptied from the damaged ballast tank. The crew of the drill ship performed an inspection of the tank and confirmed that the compromised hull was once again fully sealed. According to one of the crew members “the team did a fantastic job and the final welds amazed everyone on how clean they turned out.”

Hydrex can offer its customers the high quality of service they deserve while guaranteeing the safety of the divers at all times. Our diver/technicians are trained and qualified to perform all required repair procedures in even the harshest conditions.

Thanks to the installation of the doubler plates the ship could safely start its contract. A permanent solution can now be planned at a more convenient time.