Our teams can mobilize immediately to perform a wide range of hull repairs on any type of vessel. In this article we give you a summary of a few operations to illustrate the diversity of shell plating repairs our diver/technicians are trained for.

Sea chest insert repair in Rotterdam

A tanker suffered leakage in the starboard side sea chest of its engine room. We were asked by the owner to provide an on-site solution and sent a team to the ship’s location in Rotterdam to carry out an insert repair.

On request of the class surveyor, an NDT specialist was arranged to take thickness measurements of the starboard sea chest from inside the engine room. These measurements showed that the damage inside the sea chest was more widespread than had been presumed.

With the result of this inspection, a complete repair plan was devised in cooperation between our team leader, the ship’s crew and the classification society.

The sea chest was emptied of water and opened. All objects, including the water coolers and piping work, were removed from inside the sea chest by the crew. The affected plating was then cut away. Our diver/welders worked in shifts to fit and weld the two insert plates. This was done with class approved full-penetration welds.

When the installation was complete, a successful NDT test was carried out by an independent surveyor. As a result, the class representative gave his approval of the repair.

Fast intervention in Las Palmas ends ongoing delay

A fully loaded 180-meter bulk carrier suffered grounding damage in Las Palmas, Spain. An underwater repair was needed so that the vessel could sail to her unloading destination safely. Unfortunately, a first repair attempt proved unsuccessful. After the ship had been delayed for almost two weeks we were contacted to take over the operation and get the bulker sailing again as soon as possible.

The classification society knew we had all the certificates and skills for emergency underwater repairs. They informed the owner that the repair would be given the greenlight if Hydrex was involved. Just days after we were contacted, our repair team was on-site and ready to salvage the operation.

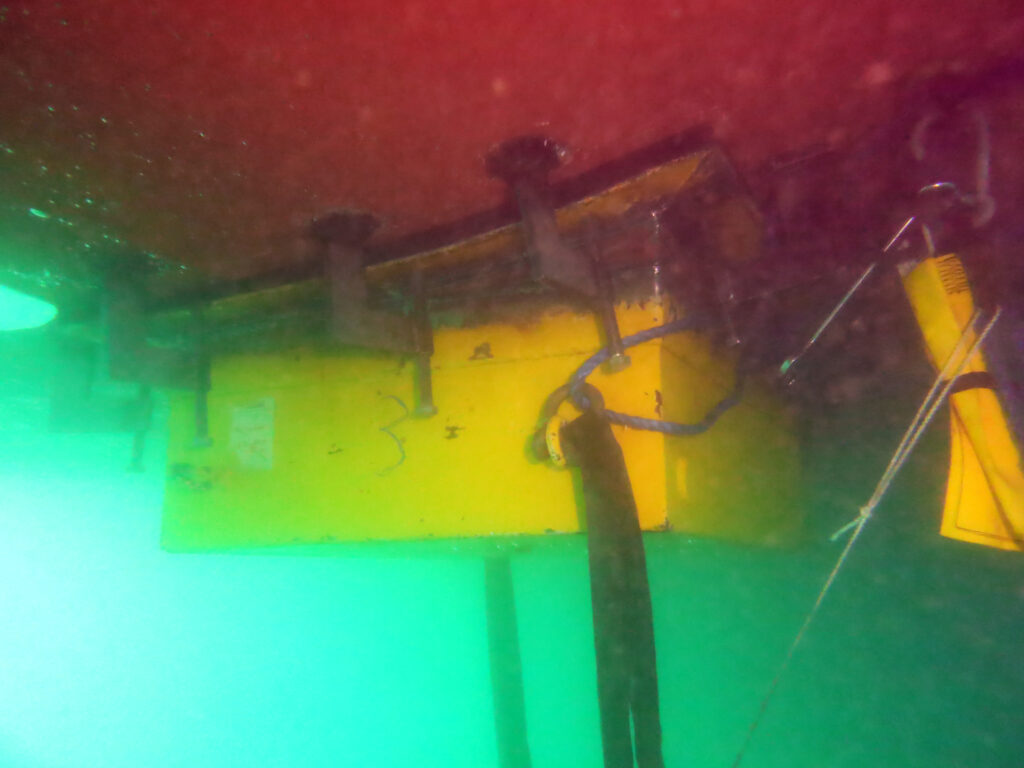

The first step of the repair consisted of removing the cofferdam that had been installed during the previous effort to repair the damage. Once this was done our diver/technicians installed two doubler plates over the affected areas of the flat bottom.

The owner and port authorities were very satisfied that Hydrex was able to step in and resolve the issue so fast. Working in shifts, we made sure that the ship would suffer no additional delay.

Repair in Port of Santander avoids drydock visit

A 115-meter LPG tanker needed to have a new insert installed on a damaged section of its flat bottom.

Because the vessel had just left drydock in Port of Santander when the damage was discovered, going back to dock was not a feasible option. Our technical department was contacted and asked to design and install a special mobdock. This would allow the shipyard to perform the repair underwater in drydock like conditions while the ship was berthed outside the yard.

A team of our diver/technicians traveled to Santander. First they performed a preliminary underwater inspection of the damage. This revealed that the required insert would be 400 x 300 mm. Next they used a special frame to take the measurements needed to design the mobdock so that it would perfectly fit the rounded shape of the hull.

The mobdock was constructed at the shipyard following the design plan provided by our R&D department. When it was finished, it was installed by our team. The shipyard could then perform the insert repair in the best possible conditions. Once the repair was finalized and approved by the representative of the classification society, our team removed the mobdock.

The LPG tanker could continue its schedule without having to wait for a drydock space to become available, much to the satisfaction of both the owner and the shipyard that performed the repair.

Shell plating replacement in Palm Beach

Besides designing and installing a tailor-made mobdock, our teams can also perform the actual insert repair. An excellent example of this was the operation performed in Palm Beach, U.S.A. on a roro vessel.

The ship had suffered corrosion damage to the aft starboard side shell plating. Because the damage was situated in the turn of bilge it was again essential that the mobdock was modified to fit perfectly over the rounded shape of the hull.

After the mobdock was installed, the frame covering the damage was removed. This allowed the team to cut away the damage and the surrounding area. A new insert plate was then positioned and welded following our class-approved procedure.

An independent inspector carried out ultrasonic tests and the repair was approved by the classification surveyor who was present during the operation.

Permanent underwater insert repair in Amsterdam

An emergency call came in on a late Friday afternoon to carry out a permanent insert repair on board a 145-meter chemical tanker that had suffered a crack in its port side grey water tank. The job was carried out during the vessel’s stop in Amsterdam.

In close communication with the superintendent of the vessel and the attending class surveyor, it was decided that a 700 x 300 mm insert would need to be installed. The new insert plate and a steel mobdock were fabricated at our headquarters in Antwerp.

By installing the new insert to repair the large crack, this area of the ship did not require further repairs during her next drydocking. The vessel could sail on time as the repair was carried out well within the stipulated time frame.

Conclusion

Know-how and experience are needed to find the best solution for any problem you might encounter with your ships. This can be a simple routine repair or a unique complex one, as illustrated by these case studies.

All repairs are performed to the highest technical standards by our teams following in-house developed procedures. These operations are approved by the major classification societies.

Our goal is to keep you sailing with no delay.

If ever you need assistance with the underwater part of your vessel, give us a call. We can then tell you if the repair is feasible and start working on its handling.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more case studies.

Underwater repair of leaking seal assembly in Trinidad

Underwater bow thruster removal and reinstallation in Australia

Scrubber overboard pipe repairs in Belgium and the Netherlands

Insert installation in Uruguay prevents loss of contract

Double stern tube seal repair on second vessel in Tasmania confirms customer’s trust