A 200 meter cruise ship experienced a failure in the feedback system of its bow thruster. We therefore mobilized a team to Phuket, Thailand to perform the necessary underwater repairs with the use of our flexible mobdocks.

These lightweight flexible mobdocks are easy to transport and are used to close off the thruster tunnel on both sides. This allows our divers to empty all water from the room and create a dry environment around the unit. In this way the required operation can be performed underwater in dry conditions, whether it entails the removal or installation of an entire unit or, as was the case with the operation described in this article, repair work on a specific part.

While on its way to Phuket, a breakdown occurred in the feedback system that specifies the position of the vessel’s bow thruster blades. Taking into account the strict schedule of the cruise ship, keeping it sailing was essential. We were contacted by the customer and asked to find a fast, on-site solution

In cooperation with the manufacturer of the thruster, a plan was devised by our technical department. Our diver/technician team would carry out an inspection and any necessary repairs afloat without removing the unit from the thruster tunnel. The customer gladly accepted this proposal as it meant he did not need to take his ship into drydock. This saved him substantial time and money.

After the essential preparations were made in our fast response center, all the lightweight equipment for the operation was mobilized to Thailand from our headquarters in Antwerp.

After arriving on-site our team set up a monitoring station next to the vessel. They then installed the flexible sheets and removed all water from the thruster tunnel. Lights and communication lines with the monitoring station onshore were also installed.

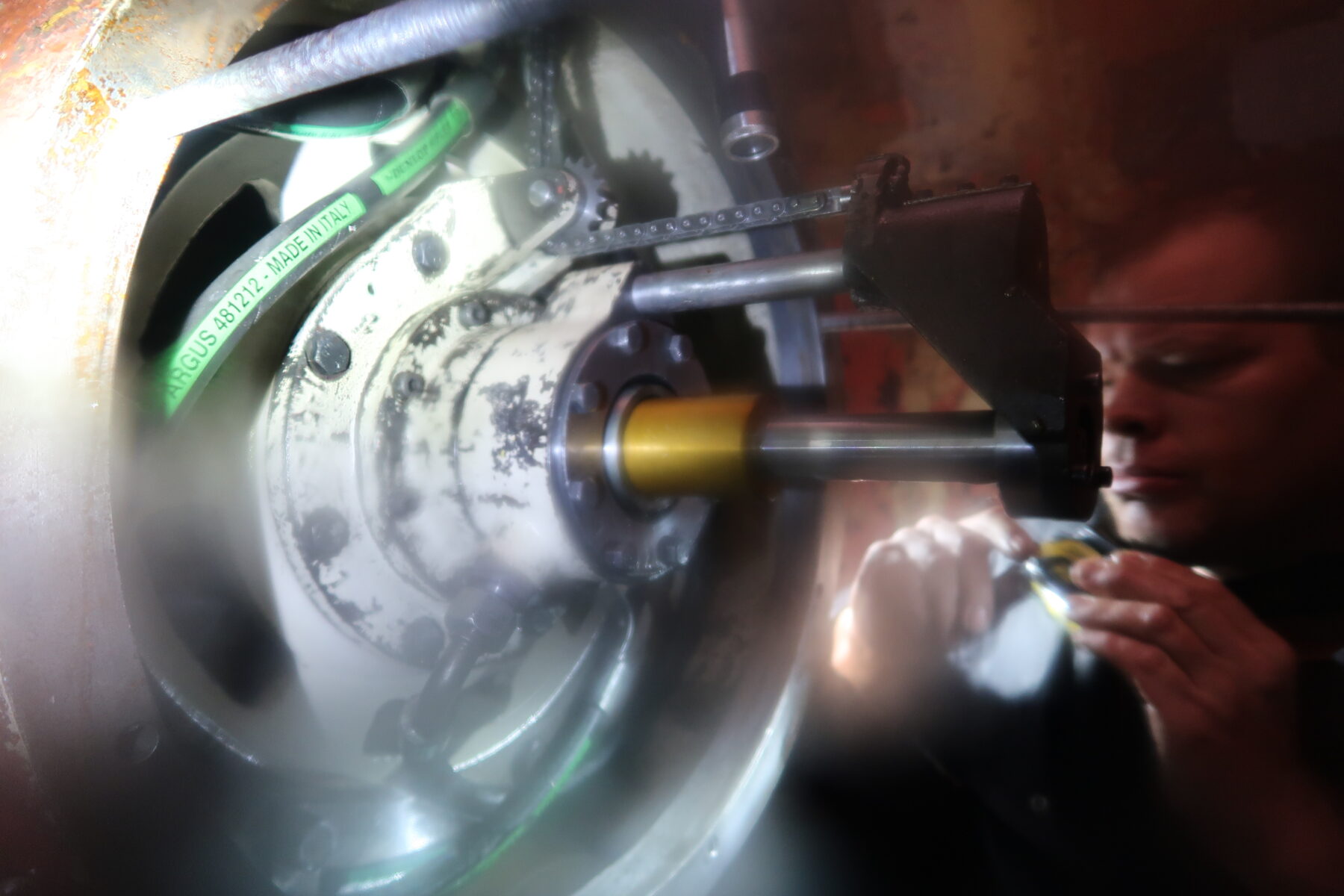

Next the bolts securing the cover of the gearbox were removed and it was opened. A video inspection of the internal part could then be performed. The feedback cable connection was broken. As a result, the chain indicating the position of the blades was not attached anymore.

The broken part was removed and inspected by OEM technician and the superintendent of the ship. There was no possibility to replace the broken part by a new one. Instead it was repaired and reinforced on-site.

The cover was then put back into place and secured again. Tests confirmed the repair to be successful. It ended with the removal of the flexible mobdocks and the performance of final tests with a fully loaded thruster.

Conclusion

Our team had a very pleasant and smooth cooperation with the crew of the ship, the manufacturer of the thruster and all other parties involved. This helped us to perform the operation as fast as possible.

By using the mobdocks the customer was able to have the damage repaired without the removal of the thruster. This allowed him to keep his vessel out of drydock and maintain the sailing schedule of his cruise ship.

During this operation we were asked to perform a hull repair on another cruise vessel at the same location. These two repairs were done back to back by this team.