To save time and money for the owner of a 200-meter roro ship, our divers removed the bow thruster of the ship and reinstalled the unit after it was overhauled while the vessel was at anchorage in Naples, Italy. By carrying out both parts of the operation underwater the ship could stay operational and did not have to go to drydock.

After the team set up a monitoring station next to the vessel, the divers started the operation with a detailed inspection of the bow thruster and tunnel. In the meantime, initial preparations were made in the bow thruster engine room for the removal of the unit so that there would be no ingress of water once it was taken out.

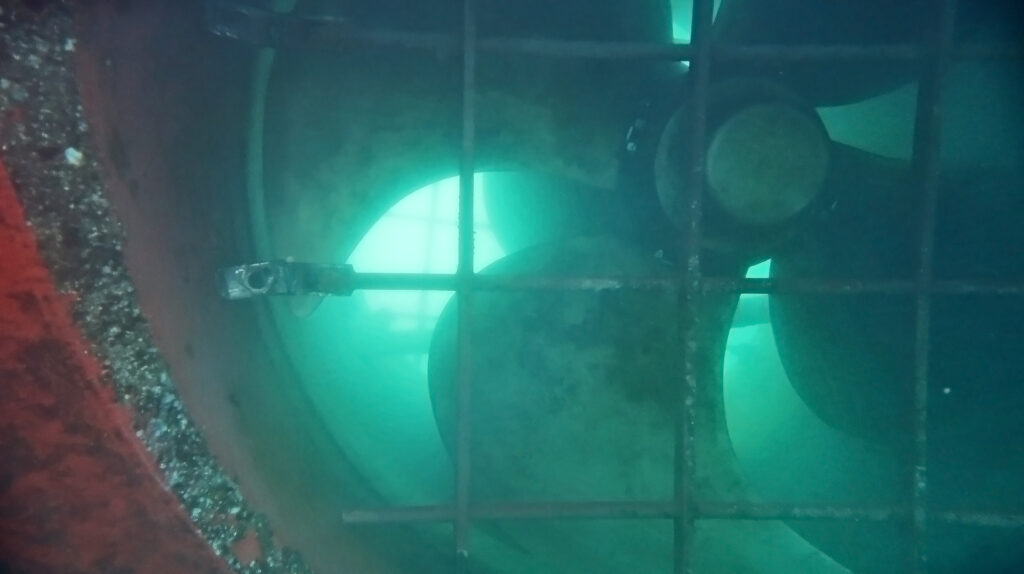

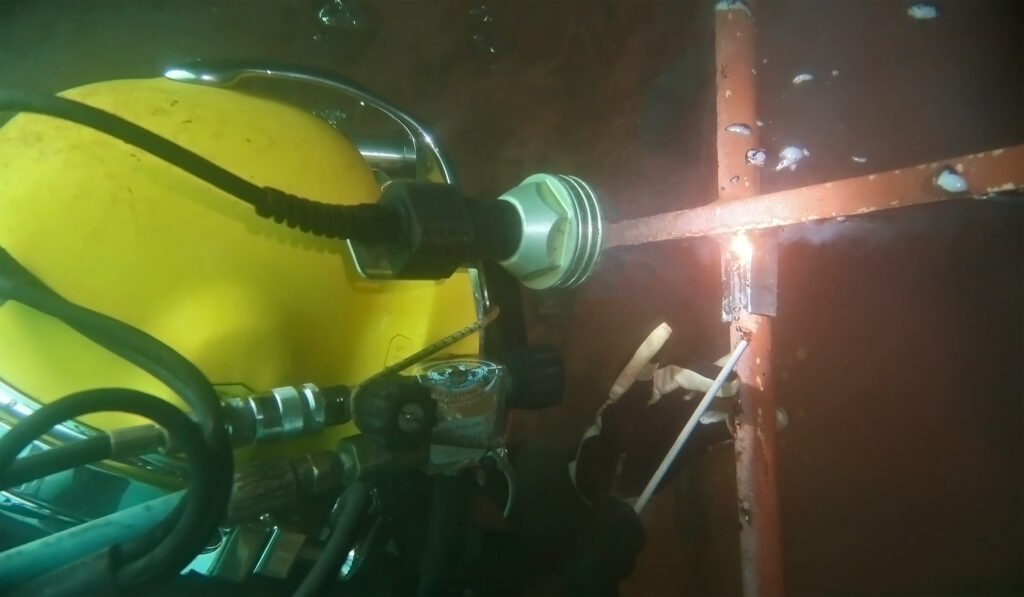

The divers first action was to take off the external thruster tunnel grids to provide access for removal of the unit. Next pad eyes were welded inside the tunnel to hoist the thruster unit up and down.

The next step was to secure the gearbox with hoisting equipment. The team then disconnected the unit from the engine room and removed it from the thruster tunnel. It was then brought to the surface where it was overhauled by the OEM’s technician, with assistance of our diver/technicians.

Because the thruster was fully assembled and prepared, it could be installed in its entirety without the need to create a dry environment in the tunnel as is required when the blades are installed separately. Our diver/technicians lowered it into the water and brought it into the thruster tunnel. The team secured the unit and connected it to the engine room.

The operation ended with the removal of the pad eyes and the reinstallation of the thruster tunnel grids.

Conclusion

We assist shipowners with almost any problem they encounter with their vessel’s thrusters. A wide range of underwater repair or maintenance work can be carried out on all types of thrusters. An entire unit can be overhauled, propeller blades or seals can be replaced or repair work on a specific part of a thruster performed by our diver/technicians while the ship remains afloat.

By performing the operation in Naples on-site and underwater our divers made it possible for the owner to keep the vessel out of drydock. Our team worked in shifts around the clock to finish the operation as quickly as possible.

If ever you would encounter a similar situation, give us a call. We can then tell you if the repair is feasible and start working on its handling.

+32 3 213 53 00

hydrex@hydrex.be