Hydrex teams carried out underwater insert repairs on ships in Zeebrugge and Antwerp. Both vessels had suffered cracks in the shell plating. In Zeebrugge a 600mm x 300mm plate was installed in the flat bottom of a 203-meter ro-ro vessel. A similar operation was carried out with a 300mm x 300mm plate on a 144-meter tanker in Antwerp. Despite the relatively small scale of both operations, they were vital for the shipowners. It allowed them to keep their vessels out of drydock and avoid having to go off hire.

Our on-site hull repair services include the renewal of both small and large areas of damaged hull plating. These repairs can be carried out above or below water, according to the circumstances, with external mobdocks. Normal commercial activities can therefore continue without disruption. These operations follow the Hydrex procedure for welding cracks and inserts in the vessel’s shell plating and they are approved by the major classification societies.

Class approved underwater hull repair

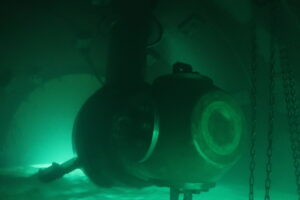

The team started the operation with a detailed inspection of both the onboard as well as the water side of the affected plating of the ro-ro vessel in Zeebrugge. This revealed a 500mm crack that needed to be repaired. Next the divers installed a cofferdam over the area.

This allowed our men to remove the longitudinal frame covering the damage. The diver/technicians could then cut away the damage and the surrounding area. Next, they positioned a new insert plate, measuring 600mm x 300mm. The insert was then welded following our class-approved procedure for insert plates, using a full penetration weld.

An independent inspector carried out ultrasonic testing and the repair was approved by the classification surveyor who was present during the operation. The diver/technicians then refitted the frame and removed the cofferdam, concluding the repair.

Permanent class approved insert operation

The same procedure was followed during the operation in Antwerp. The only differences being that the gas tank adjacent to the damage needed to be declared gas free before the team could begin the operation and that, besides the framework, a pipe needed to be removed and reinstalled afterwards.

Because the crack was slightly smaller, a 300mm x 300mm plate was enough to replace the damaged area. The affected area was situated right next to the sea chest in the turn of bilge. It was therefore essential that the cofferdam was modified to fit perfectly over the rounded shape of the hull.

Conclusion

All operations were performed to the highest quality standards by in-house trained diver/welders. We have a wide range of cofferdams at our disposal as well as certified plating which we can mobilize immediately.

If ever you would encounter a similar situation, give us a call. We can then tell you if the repair is feasible and start working on its handling.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more insert repairs and other case studies.

Underwater bow thruster operation in Algeciras

Stern tube seal repairs above and below the waterline

Scrubber overboard pipe repairs in Belgium, France, Spain and Malta

Permanent underwater insert repair on tanker in Amsterdam

Hydrex performs propeller repairs as winter arrives