As part of the Hydrex group, our office in Algeciras takes advantage of our 50 years of experience in the ship repair and maintenance industry. The ideal location of the office allows for a fast response in the Bay of Gibraltar and Algeciras.

Hydrex Spain offers a large variety of maintenance programs and underwater and afloat repairs for shipowners and the offshore industry.

Diving conditions are very good in Algeciras making it a perfect location for repair work. The shelter of the bay and the visibility are ideal to anchor a vessel and have repair or maintenance work carried out. For all ships making their way across the Atlantic to the American continent.

Algeciras is also an ideal place for berthing or bunkering.

Maintenance

Available for vessels of any size, underwater maintenance services include propeller cleanings, replacement of anodes, speed logs or echo sounders, class accepted video surveys, visual and photo surveys or tail-shaft wear down readings.

Underwater inspections represent a small investment and, if properly done, have the potential to save an owner a great deal of money. If any damage is discovered, the repair work can already start while any additional equipment that might be required is mobilized.

Repairs

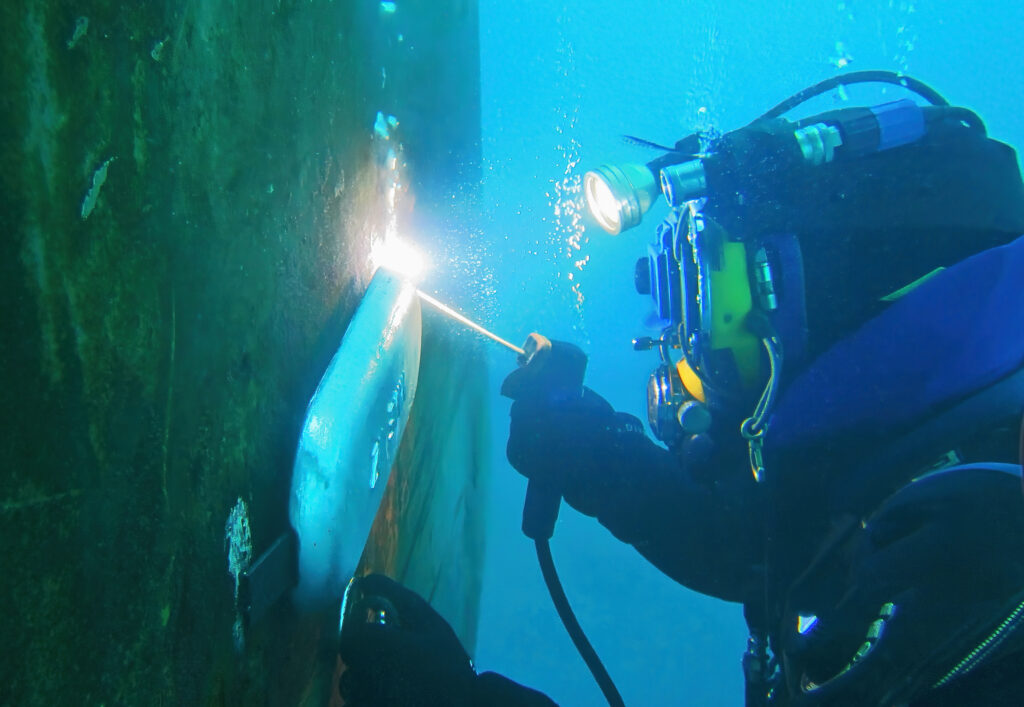

Repair work consists of propeller repairs, temporarily or permanent shell plating crack repairs, seal , thruster or rudder repairs and any type of welding work. Hydrex Spain also offers a wide range of afloat repair operations including any type of steel and (scrubber) pipe repair and conversions.

All operations are carried out by highly qualified diver/technicians all of whom have extensive experience and certified by the ship’s classification society.

The first article in this magazine talks about a thruster operation in Algeciras. Below are some further case studies of operations performed by our divers in Algeciras.

Class-approved underwater shell-plating replacement

A 135-meter tanker suffered cavitation damage to the inside shell-plating of one of its ballast water tanks. We mobilized a team to perform a permanent insert repair so as to avert an unscheduled drydock visit for the vessel.

After arriving on site, our team of diver/technicians started with an on-board and underwater inspection of the damaged area. This revealed that the crack was 150 mm long. In close communication with the superintendent of the vessel and the attending class surveyor, it was decided that a 300 x 300 mm insert would need to be installed.

The divers started the operation by removing a part of the bilge keel. This was required to install our customized cofferdam on the waterside of the affected plating. Because it needed to fit the rounded shape of the hull perfectly it was tailor-made at our fast response center.

As agreed with the classification society, the team then cut away an area measuring 300 x 300 mm. Next, they prepared the edges of the opening for the insert and positioned the new plate. The insert was then welded using a full penetration weld.

An independent inspector carried out ultrasonic testing and the repair was approved by the classification surveyor who was present during the operation.

By removing the cracked section of plating and installing a new insert, this area of the ship does not require further repairs during its next drydocking. The vessel could sail on time as the repair was carried out well within the stipulated time frame.

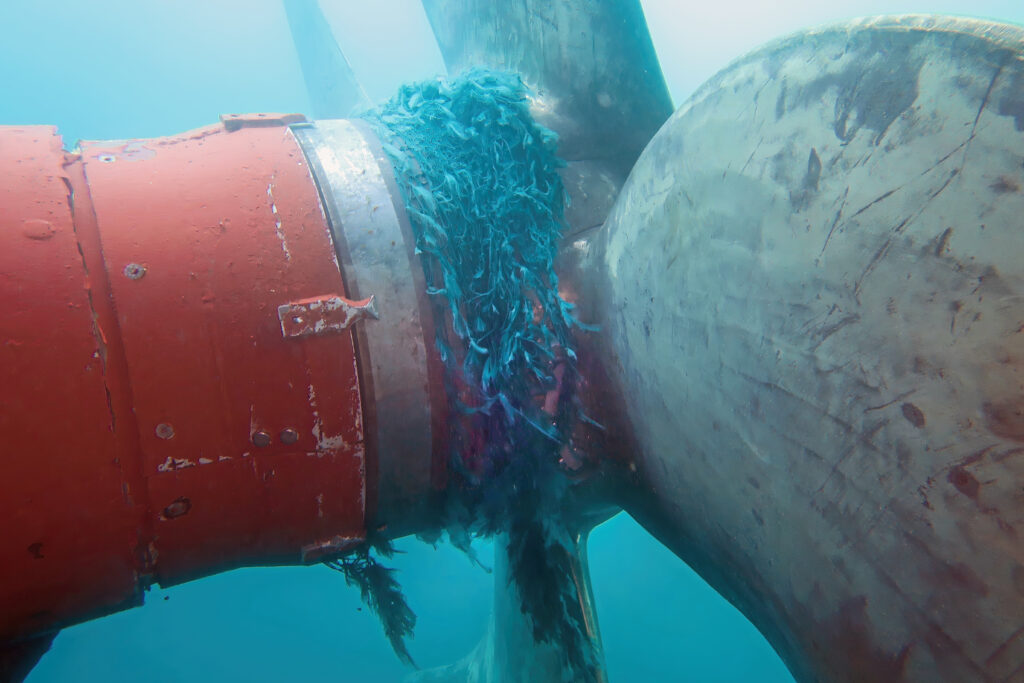

Underwater stern tube seal repair

One of our teams recently carried out an underwater stern tube seal repair on a tanker berthed in Algeciras. The ship was suffering from an oil leak and no drydock was available close by. Our divers replaced the damaged seals underwater using one of our flexible mobdocks. This saved the owner an expensive and time-consuming trip to a drydock further away.

During the operation our divers removed the three damaged seals and replaced them with new ones. Working together with the OEM allowed us to provide our customer with original spare parts which guarantees the best quality material. A technician of the seal manufacturer was also present during the operation.

Our team was able to carry out the entire repair on-site and underwater with our flexible mobdock technique. Because all the required material is ready to be transported at all times, no time was lost making preparations.

We organized everything from start to finish for the owner. After the seals had been successfully replaced, he could sail his vessel to its next stop free of oil leaks.

Hydrex Spain S.L.

Poligono Industrial Palmones II

Calle Dragaminas Nave N29

11370 Algeciras

Spain

Phone: +34 956 675 049 (24/7)

E-mail: info@hydrex.es

If ever you need assistance with the underwater part of your vessel, give us a call. We can then tell you if the repair is feasible and start working on its handling.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more case studies.

Underwater bow thruster removal and reinstallation in Naples

Start saving fuel with your propeller cone fin now

Restoring propellers above or under the water

Permanent underwater insert repair on bulker in France

Double stern tube seal repair on roro vessel in Tasmania