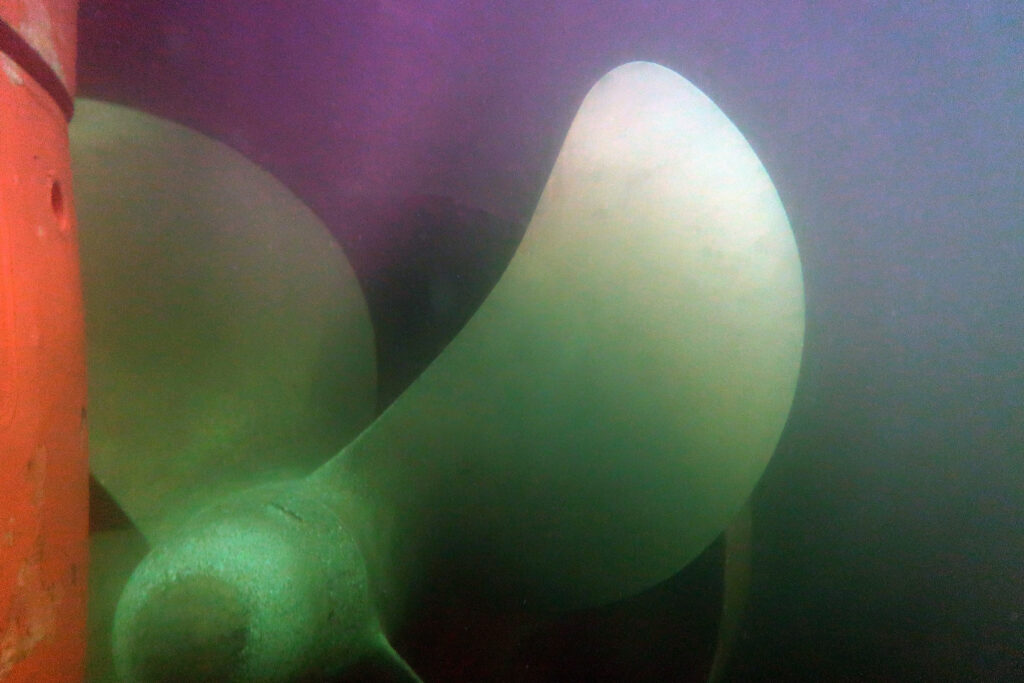

With three of the four blades of its propeller severely bent due to impact with ice, a 189-meter bulker needed a fast, on-site solution. We sent a team to Tallinn, Estonia mid-winter to restore the propeller’s balance and efficiency. They carried out modifications to the blades while the ship was at anchorage.

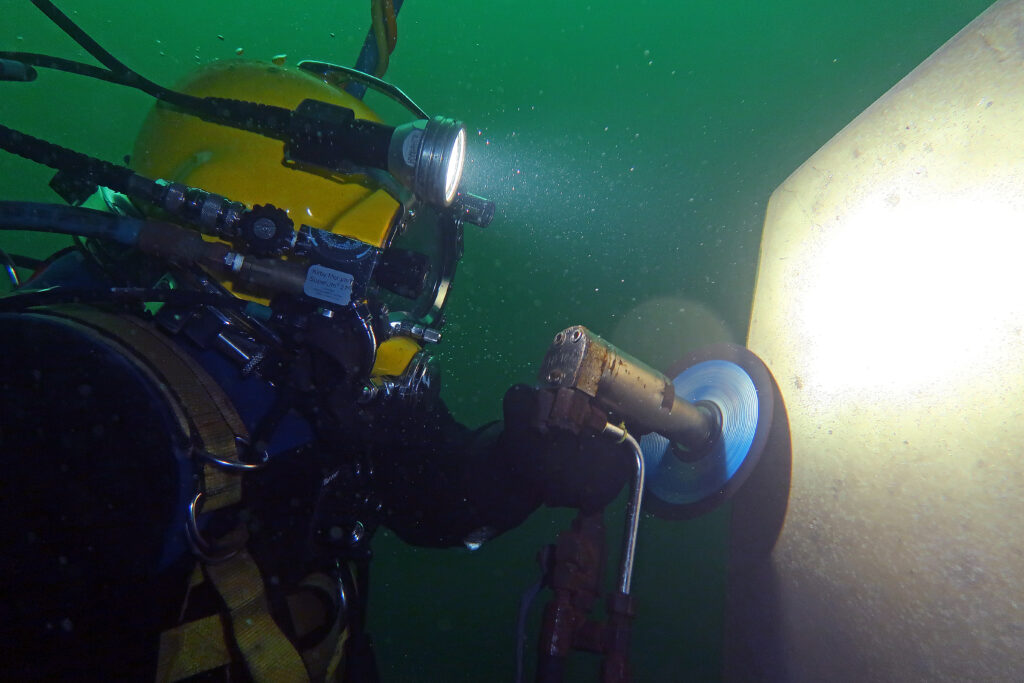

Our men first performed a detailed underwater inspection of the damage. This showed them that blade A had suffered no damage while the opposite blade C was bent over an angle of 30°. This meant that the original shape of the blade could easily be restored with our in-house developed, cold-straightening machine.

The other two blades were more severely bent, with blade D bent as much as 120°. This was unfortunately too much to be straightened. Cropping the blade was the only option. To keep the propeller’s balance, the opposite blade also needed to be cropped using the same cropping line. This was done using our propeller blade cutting equipment, which was also designed by our R&D department.

After both blades were cropped, the cutting lines were polished to minimize the chance of cavitation and optimize the blades’ efficiency. Our team made sure they left enough material so that the removed blade tips could be easily welded back onto the rest of the blade during the next drydock visit.

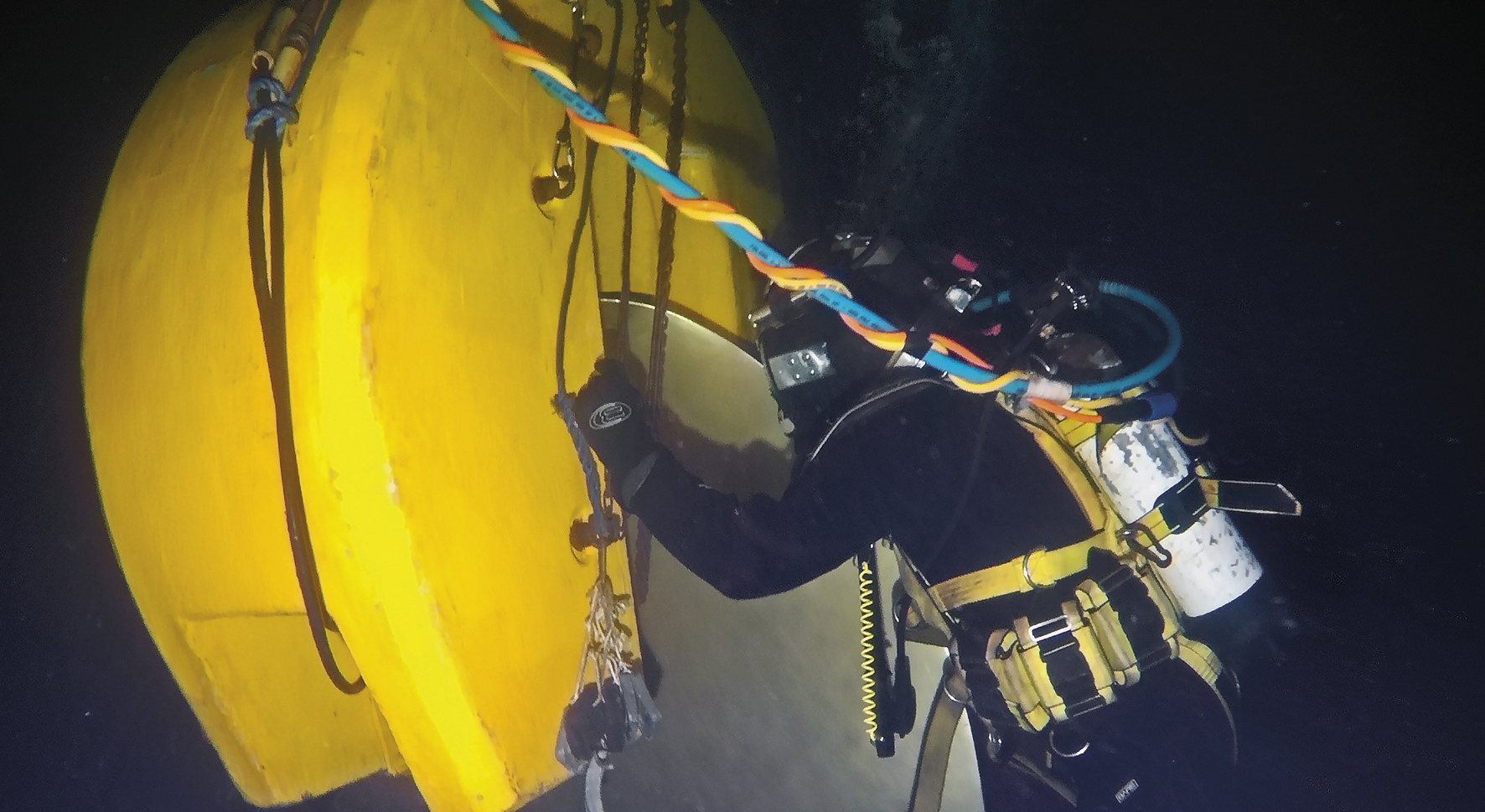

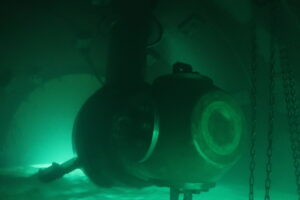

While our divers were working on the propeller blades underwater, the team leader ashore monitored video links from underwater cameras on the divers’ equipment. The exact dimensions and position of the damage could then be communicated between the divers and the technical team supervising the operation. This is essential because the calculations need to be perfectly accurate to achieve the best results in terms of propulsion efficiency.

Conclusion

Close to 50 years of experience with propeller repairs has given us the tools and know-how to offer fast repair and modification services to vessels around the world. All types of operations can be carried out fast and efficiently afloat and underwater.

If you have any questions regarding a possible propeller repair, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more propeller repairs and other case studies.

Underwater propeller blade replacement in Tasmania

Underwater bow thruster operation in Algeciras

Scrubber overboard pipe repairs in the Netherlands, France and Spain

Propeller blade cropping in Ghent avoids costly drydocking

Leaking seal assembly fixed underwater in Antwerp