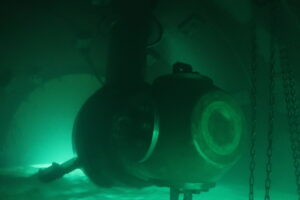

Two parts of the tip of one of the four propeller blades of a 190-meter bulker were damaged. They needed to be cropped to restore the propeller’s efficiency. We therefore sent a team of diver/technicians to the ship’s location in Germany to carry out the repair afloat.

Having developed different procedures for different kinds of damage, our teams are equipped and trained to make the best out of a bent or broken propeller. Ideally, the in-house developed cold straightening technique is used. This procedure enables Hydrex technicians to straighten damaged blades in-water, allowing commercial operations to continue without the need to drydock.

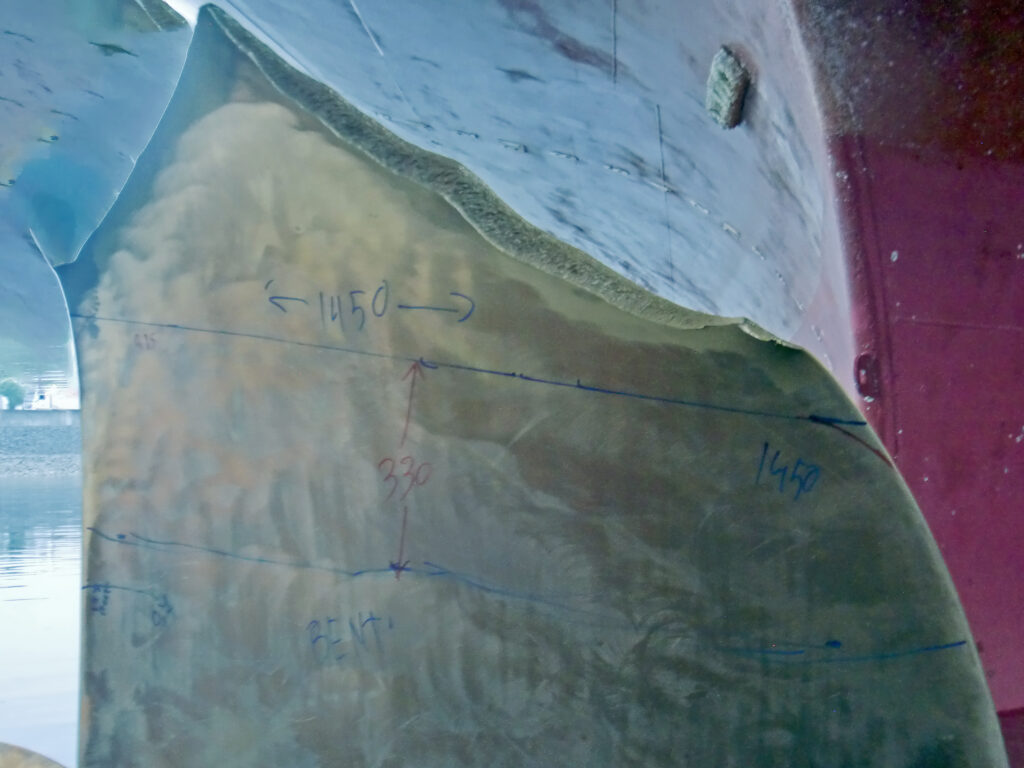

In the following example cropping was the only option, since the type of damage to the propeller blade did not allow cold straightening. This kind of repair is carried out with the propeller blade cutting equipment developed by our research department. In cases like this, where there is an even number of blades, an identical piece will be cropped from the opposite blade to restore the hydrodynamic balance of the propeller. By doing so, the best possible efficiency is obtained.

Single-day operation restores efficiency

After the equipment arrived at the vessel’s location the team started the operation with a detailed survey of the affected propeller blade. The team then used the information acquired during the inspection to calculate and determine the correct measurements needed to modify the trailing edges of the propeller blade. Next the divers cropped the blade and ground its edge to give it the correct radius. The opposite blade was modified using the exact same cutting line, to give the propeller back its balance.

When the cropping was complete, the Hydrex technicians polished the blades to make sure that any remaining loss of efficiency would be minimal.

Conclusion

Over fifty years of experience with propeller repairs have given us the tools and know-how to offer fast repair and modification services to vessels around the world. All types of operations can be carried out fast, fluently and efficiently afloat and underwater.

In this case the repair took less than a day. This ensured there was no unwelcome delay to the vessel’s schedule.

If you have any questions regarding a possible propeller repair, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more propeller repairs and other case studies.

Underwater propeller blade replacement in Tasmania

Underwater bow thruster operation in Algeciras

Scrubber overboard pipe repairs in the Netherlands, France and Spain

Propeller blade cropping in Ghent avoids costly drydocking

Leaking seal assembly fixed underwater in Antwerp