When damage to propellers occurs due to impact with ice and other debris we can help you, even if the damage is quite extensive.

A ship with bent or cracked propeller blades might experience severe vibrations while sailing. The classification society may demand a repair before the vessel is allowed to continue its voyage. Our teams can restore the propeller’s balance and efficiency, resulting in class approval.

A propeller modification can easily be combined with any other maintenance or repair operation that needs to be carried out on the vessel. Thanks to the flexibility of our teams this allows a vessel to keep its schedule.

Straightening, cropping and any other repair done afloat

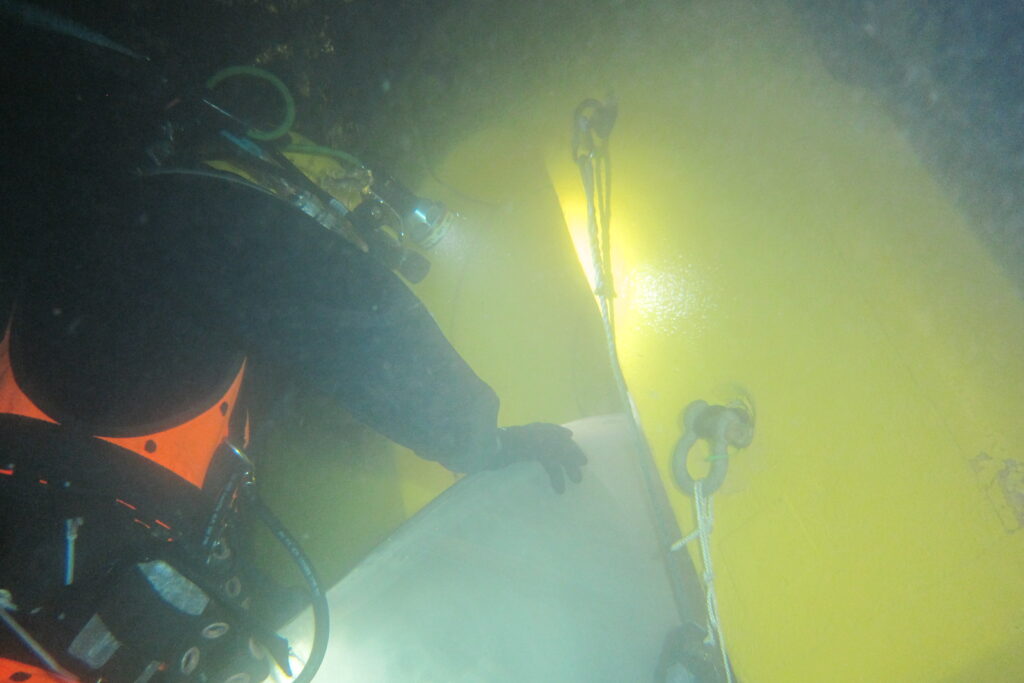

By taking advantage of the in-house developed cold straightening technique, damaged blades can be straightened underwater, allowing the ship to return to commercial operations without the need to drydock.

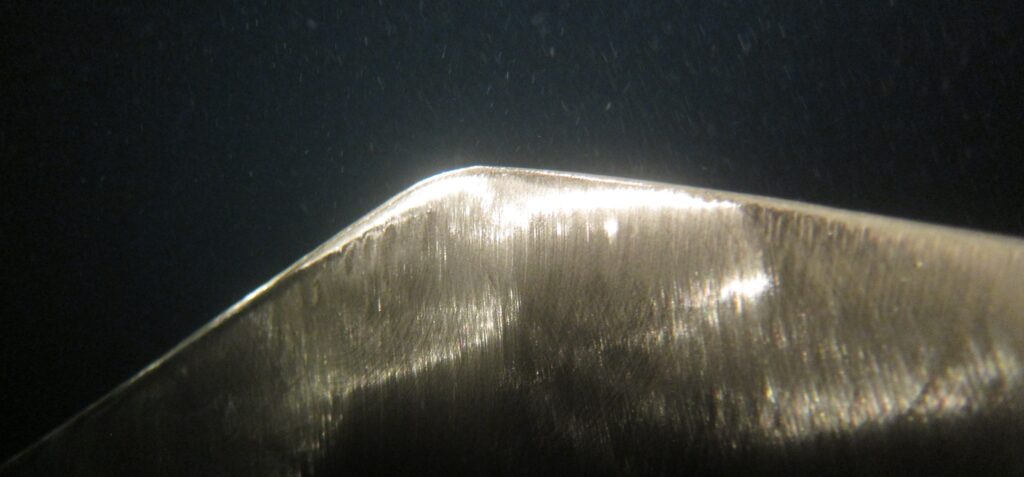

If straightening is not an option, the affected area of the blade will be cropped. This is done to achieve the greatest possible efficiency. Cropping is carried out using our propeller blade cutting equipment.

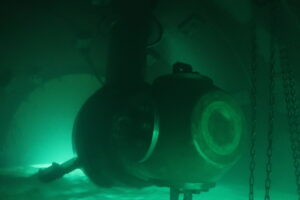

Our teams can also carry out any other repair work on the propeller. Examples of this are the removal and reinstallation of entire propeller blades or replacement of the propeller seal ring.

Below you can read some case studies that illustrate the wide range of afloat operations our teams can carry out.

Smoothing the creases

One of the propeller blades of a 180-meter bulker was severely bent. A fast, on-site solution to restore the propeller’s balance and efficiency was needed. We therefore sent a team to the ship’s location in Rotterdam with one of our workboats.

After the equipment arrived the team started the operation with a detailed survey of the ship’s propeller. This revealed that one of the other three propeller blades was also bent slightly. It was decided to straighten this blade as well.

With the survey completed and in close communication with the team leader in the monitoring station onshore, the divers returned the bent blade to its original state. When the straightening was complete, our technicians polished the blade to make sure that any remaining loss of efficiency would be minimal. The same procedure was then repeated on the other damaged blade.

Ice and cold no match for Hydrex

The conditions for a similar repair in Tornio, Finland were a lot less warm. All 4 blades of a 144-meter general cargo ship were bent. We mobilized a team to straighten the blades using the same procedure as on the vessel in Rotterdam. They traveled through the snowy landscapes with two vans and the needed equipment to the ship’s location.

During the operation our divers had to work in water filled with chunks of ice, but these conditions offered no problem for them. They are used to adapt to different circumstances and carried out the repair without any loss of quality.

By performing these repair and maintenance operations underwater and on-site Hydrex saves ship owners precious time and money. It allows ships to return to commercial operations without the need for drydocking.

Afloat propeller blade cropping in Dunkirk

The four blades of a 229-meter bulker’s propeller were severely bent. An on-site solution was needed to restore the propeller’s balance and efficiency. A team was therefore mobilized to the ship’s location in Dunkirk, France, to modify the damaged blades.

After the equipment arrived at the vessel’s location the team started the operation with a detailed survey of the affected propeller blades. The inspection revealed that the four blades were bent over angles of up to 90 degrees.

The team then used the information acquired during the inspection to calculate and determine the correct measurements needed to modify the trailing edges of the propeller blades. Next the divers cropped the blades and ground their edges to give them the correct radius. When the cropping was complete, the Hydrex technicians polished the blades to make sure that any remaining loss of efficiency would be minimal.

The bulker could continue its schedule without going offhire to drydock and with the performance of its propellers restored.

If you have any questions regarding a possible propeller repair, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more propeller repairs and other case studies.

Underwater propeller blade replacement in Tasmania

Underwater bow thruster operation in Algeciras

Scrubber overboard pipe repairs in the Netherlands, France and Spain

Propeller blade cropping in Ghent avoids costly drydocking

Leaking seal assembly fixed underwater in Antwerp