Recently we mobilized our diver/technician teams to vessels in Belgium and France to carry out stern tube seal replacements. In Brest the repair was carried out on a 150-meter cruise vessel, and in Antwerp, on a 237-meter container ship.

Both ships were leaking oil, making an on-site repair necessary. Using a Hydrex flexible mobdock we were able to carry out these operations on-site and underwater, saving the owners an expensive and time-consuming trip to drydock.

Helping a cruise ship stay on schedule

Once the operation in Brest was approved, all preparations were handled swiftly and the lightweight equipment was mobilized almost immediately from our fast response center.

After arriving on-site, the diving team first set up a monitoring station next to the vessel. The operation started with a thorough underwater inspection of the stern tube seal assembly, and removal of the rope guard.

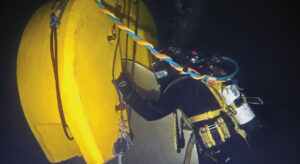

Our divers then cleaned the assembly and installed the flexible mobdock, thus creating a dry underwater environment where they could work in drydock-like conditions.

The split ring was removed and brought to the surface to be cleaned. After cleaning the entire assembly, the divers removed the first seal and replaced it with a new one which was then bonded. Next, they did the same for the other seals.

A successful operation was concluded with leakage tests, the removal of the flexible mobdock and the reinstallation of the rope guard.

Easy mobilization with dedicated workboat

A team traveled to the container ship’s berthing location in Antwerp on one of our workboats. These workboats are fully equipped as dive support vessels with hydraulic cranes, winches, nautical and communication equipment, and a dive control room. They are stationed in Antwerp and Rotterdam and can be used for a wide range of operations in Belgium, the Netherlands, the United Kingdom and France.

With Hydrex organizing everything from start to finish, the owner did not have to worry about making any arrangements for the repair. After the seals had been successfully replaced, the vessel was able to sail to its next stop free of oil leaks.

Working together with the OEM allowed us to provide our customer with original spare parts which guarantees the best quality material. A technician from the seal manufacturer was present during the operation.

All our offices are equipped with the latest facilities, lightweight equipment and tools. This allowed for a timely arrival of our team with everything they needed to successfully complete the job.

We help keep ships afloat, operational and in business

We offer maintenance services and repairs on all parts of the underwater ship’s propulsion systems and the hull. Operations are class approved and carried out at lay-by berths or alongside the dock while commercial activities continue. All is done with qualified and experienced diver/technicians, state-of-the-art equipment, and advanced techniques.

If ever you would encounter a similar situation, give us a call. We can then tell you if the repair is feasible and start working on its handling.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more seal repairs and other case studies.

Underwater stern tube seal repair on container ship in Algeciras

Stern tube seal repairs close to home and far away

Scrubber overboard pipe repairs in Belgium, France, Spain and Malta

Propeller blade modifications in Estonia

Double underwater stern tube seal repair in Tasmania