Our diver/technicians can perform a wide range of repair or maintenance work on bow thrusters. An entire unit can be overhauled, propeller blades and seals can be replaced or repair work on another specific part of a thruster can be performed on-site. These repairs are performed in cooperation with all OEMs and can be carried out while the ship stays afloat with minimum impact on its schedule.

Our goal is to offer you the most efficient solution while maintaining the highest safety and quality standards. This article gives an overview of some of the more important recent bow thruster repairs carried out by our teams.

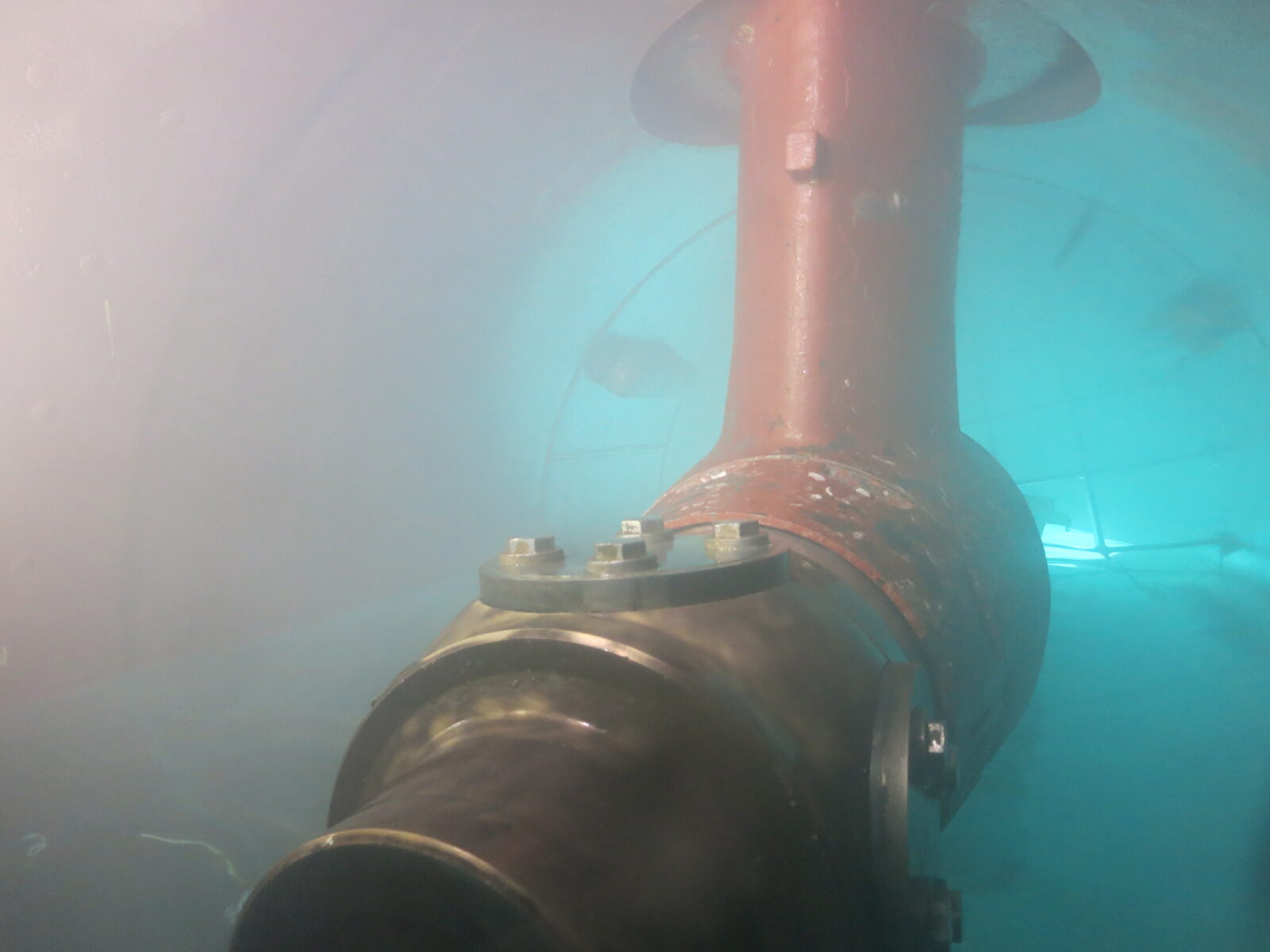

Underwater bow thruster removal in Rotterdam

One of our teams removed a bow thruster from a 170-meter container ship. This was done during a stop in Rotterdam. The unit needed to be overhauled and the operation had to be carried out within a very short window that would fit the schedule available to the vessel’s owner.

The team mobilized to the ship’s location using one of our workboats loaded with all the needed equipment. These workboats are stationed in Antwerp and Rotterdam and can be used for a wide range of operations. This enables rapid deployment. It also increases flexibility, which was essential during an operation like this.

We carried out the removal following the specific procedures required by the involved OEM. This allowed us to remove the thruster unit with the blades still attached, speeding up the operation. Simultaneously the team sealed off the tunnel from the bow thruster room. Once the unit was lifted onto the quay it was prepared for transport to the workshop.

By performing the operation on-site and underwater our divers made it possible for the owner to keep the vessel out of drydock. Our team worked in shifts around the clock. They finished the job well within the available time frame. This allowed the ship to sail on schedule, which was a key benefit for the owner.

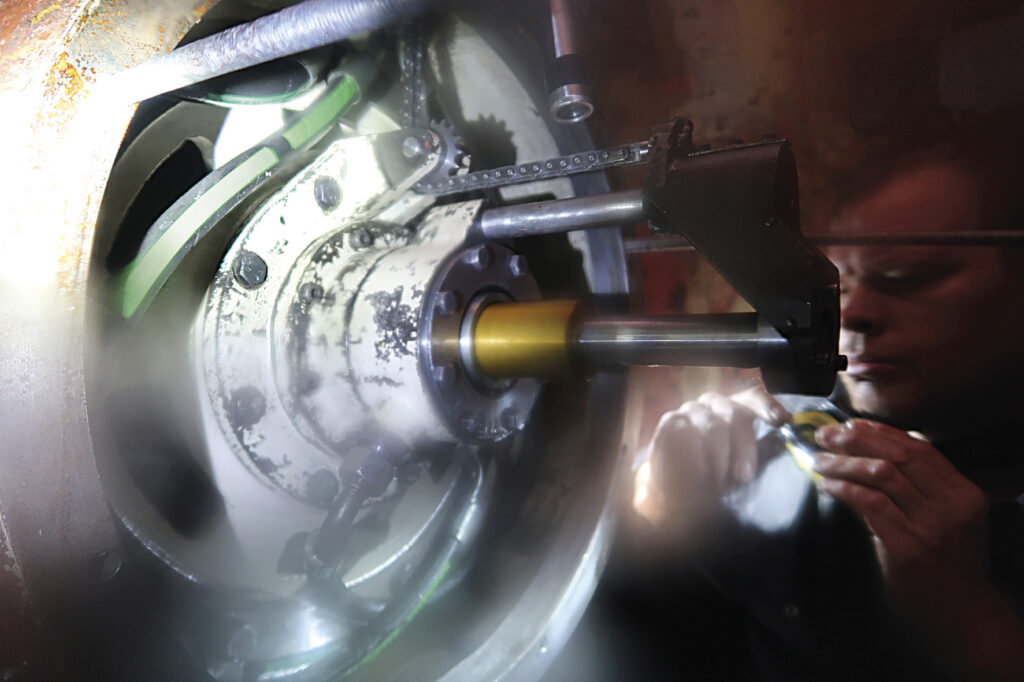

Thruster repair afloat in Phuket

A 200-meter cruise ship experienced a problem with its bow thruster. We therefore mobilized a team to Phuket, Thailand to perform the necessary underwater repairs with the use of our flexible mobdocks.

A breakdown occurred in the feedback system that specifies the position of the vessel’s bow thruster blades. Taking into account the strict schedule of the cruise ship, keeping it sailing was essential. We were contacted by the customer and asked to find a fast, on-site solution.

In cooperation with the manufacturer of the thruster, a plan was devised by our technical department. Our diver/technician team would carry out an inspection and any necessary repairs afloat without removing the unit from the thruster tunnel. The customer gladly accepted this proposal as it meant he did not need to take his ship into drydock. This saved him substantial time and money.

Our team had a very pleasant and smooth cooperation with the crew of the ship, the manufacturer of the thruster and all other parties involved. This helped us to perform the operation as fast as possible.

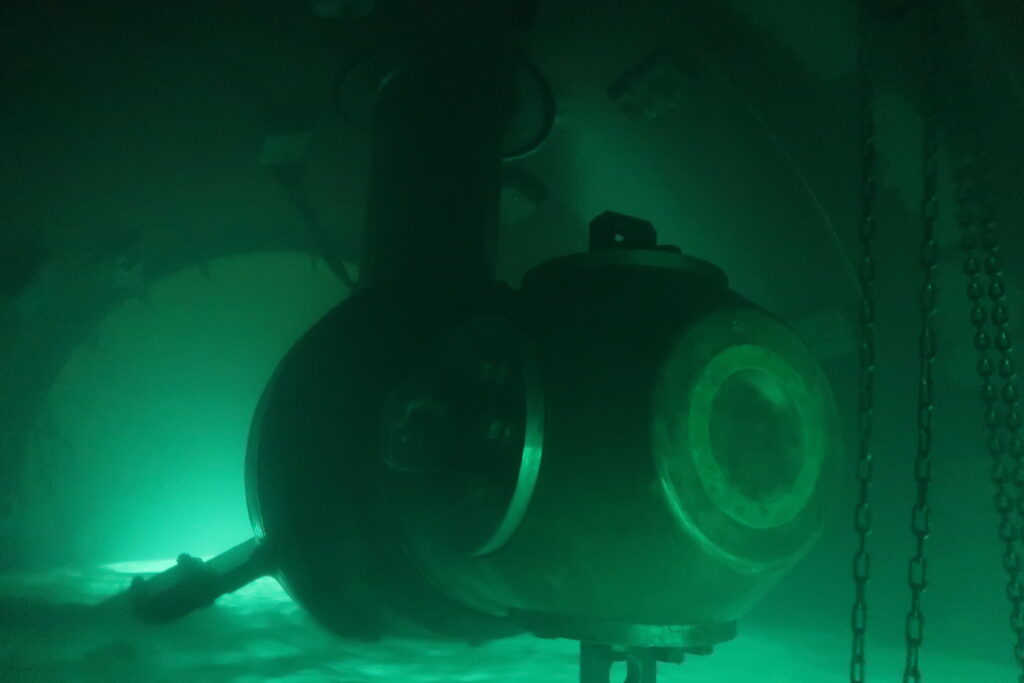

Underwater bow thruster operation in Algeciras

We removed a bow thruster from a 229-meter bulk carrier. Two weeks later the overhauled unit was reinstalled. Both operations were done during stops in Algeciras, Spain and had to be carried out within the tight schedule available to the charterer.

To keep the impact on the ship’s schedule to the absolute minimum our divers performed an inspection of the bow thruster unit and tunnel, followed by some preliminary work while the vessel was berthed at a lay-by. The ship could then shift and start cargo operations while our men performed the rest of the operation without any hindrance to the loading schedule.

If you have any questions regarding bow thruster or other repairs, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be