Recently Hydrex installed propeller cone fins on two chemical tankers: one in Antwerp and one in Rotterdam. Both operations were carried out with our dive support workboats. Stationed in these ports, they allow for immediate mobilization.

A direct result of these underwater operations is that an owner can instantly start benefitting from the fuel savings a propeller cone fin brings. He does not have to wait until the next scheduled drydocking for the installation.

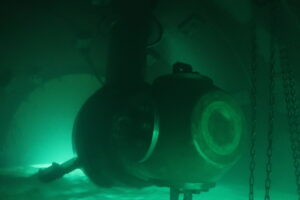

Propeller caps like these can recover energy loss of a propeller hub vortex in the propeller’s slipstream. This decreases fuel consumption from 3% up to 5% according to the manufacturers and reduces cavitation on rudders and hulls. Hydrex can install propeller cone fins underwater on any size and make of propeller, on both new build or in-service vessels.

Installation afloat prevents a long wait for fuel savings

We carry out these operations following the specific procedures required by the involved OEM, adapted for an underwater installation.

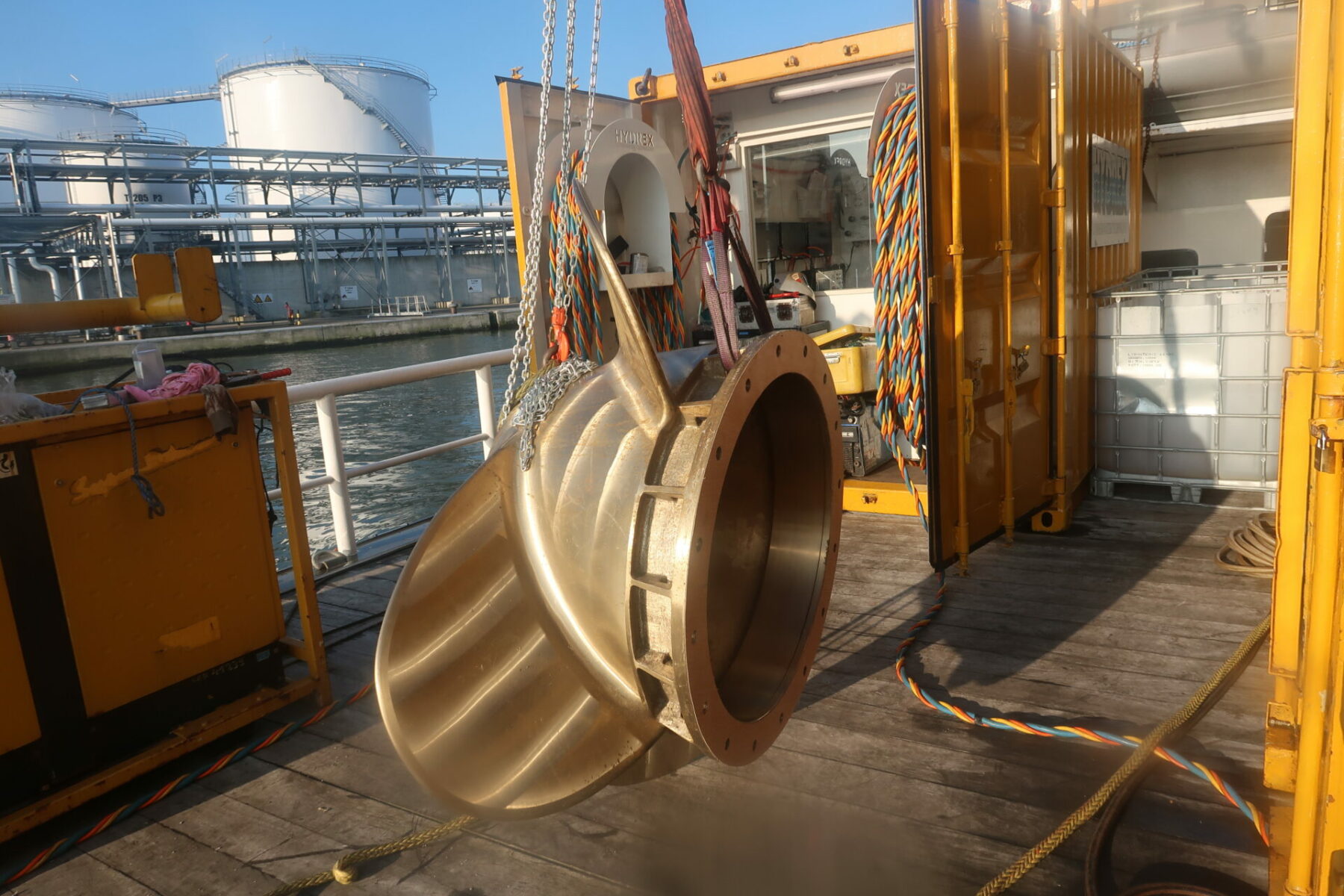

After a preliminary inspection the divers remove the propeller cap and clean the flange where the device is to be installed. They then lower the propeller cone into the water and position it on the propeller. The bolts are put on the correct torque and secured. Hydrex teams can work in shifts around the clock to finish the operation as quickly as possible.

The owner of the vessel can start enjoying the fuel savings the propulsion improving device creates right away. Not having to wait for the next scheduled drydocking to have the propeller cone fin installed can win him up to four years of fuel savings. In contrast, he will have earned back the cost of the underwater installation in only a few months. The savings are considerable.

If you have any questions regarding a possible propeller cone fin installation, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more propeller repairs and other case studies.

Underwater propeller blade replacement in Tasmania

Underwater bow thruster operation in Algeciras

Scrubber overboard pipe repairs in the Netherlands, France and Spain

Propeller blade cropping in Ghent avoids costly drydocking

Leaking seal assembly fixed underwater in Antwerp