Home - Underwater repairs - Hull repairs

Hull repairs

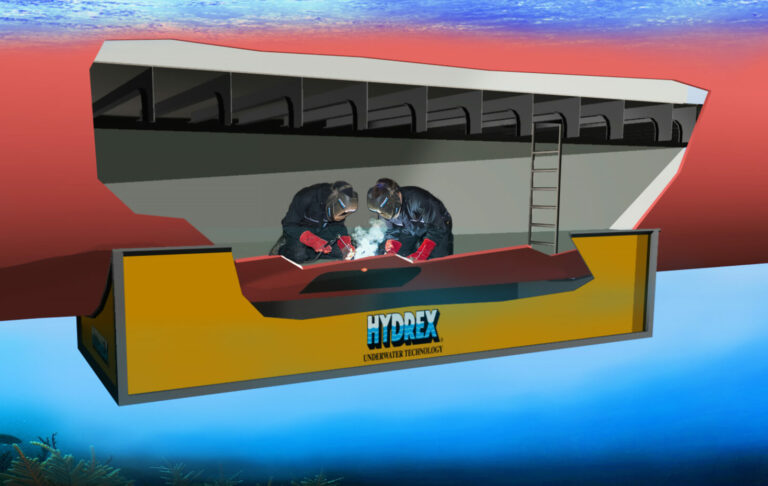

We offer class approved hull repairs combining both underwater cofferdam installation and inside dry welding. Both parts of such an operation are performed by the same team of in-house trained diver/welders working at the highest quality standards.

Class approved hull repairs

Hydrex permanent welding repairs include the following operations:

- Renewal of damaged hull plating, large or small areas

- Crack repairs by use of cofferdam

- Pipe/flange repairs or replacements

- Clad welding of cavitated areas

- Inwater seachest installation

These operations are carried out afloat with the use of an external cofferdam. In most cases normal commercial activities can therefore continue without disruption. We have a wide range of standard cofferdams available at our offices, but a tailor-made cofferdam can also be created to fit a specific hull shape.

Grade A wet welding certificate

We have received the approval to carry out classification certified grade A wet welding. To guarantee the required high standard of these underwater welds, NDT tests were performed by ABS surveyors before the certificate was awarded.

The certificate was given to carry out grade A groove welding underwater. Most companies with a wet welding certificate can only carry out fillet welds and this often only to grade B or C. Cavitation or corrosion damage on rudders, clad welding, rope guard repairs, mewis duct repairs, … can now be done with permanent welding.

With a class B weld an inspection of the weld is required every three months. With class A welding the deadline for an inspection is much longer. This is decided by the attending surveyor on a case by case basis.

Any required inspection will be for the underlying problem causing the damage and not for the welding work. An internal structural problem causing damage will not always be handled after the repair and will need to be followed up. For instance, doubler repairs can never be permanent because the doubler is installed over the damaged plating instead of replacing it (as is the case with insert repairs).

With class A underwater welding only a note is made stating that the affected area needs to be looked at during the next scheduled inspection. This is very important for tankers as a clean class certificate is requested by most charterers.

Even for non-class items like rope guards the certificate is useful because it shows our customers that our diver/welders can carry out high quality underwater welding work. This is very important for offshore units where high quality standards need to be verified before welding operations like doubler repairs can be performed.

Contact us for more information on hull repairs or other underwater repairs. We are at your disposal 24/7.

Video of our divers performing underwater welding. This was part of a complex hull repair that was done in cooperation with a shipyard in Greece.

News and projects

Permanent insert repair executed in port, eliminating unnecessary downtime

Unexpected hull damage often puts shipowners under pressure to act quickly, with drydocking frequently seen as the only viable option.

Temporary doubler plate installation saves owner costly emergency drydock

When a roro ship at anchorage in Sohar, Oman, was found to have severe damage to its bottom hull plating

Shell plating repairs across Europe

For the operations in this article our teams traveled across Europe to perform hull repairs on a wide range of