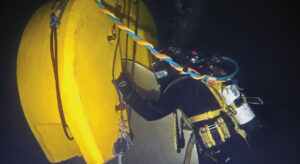

Our divers recently carried out the successful installation of a T-Foil on a high-speed craft ferry during the vessel’s stay in Fort Lauderdale, Florida. The project was performed underwater, allowing the vessel to continue its operations without the need for drydocking, minimizing downtime and maintaining the owner’s schedule.

Project overview

T-Foils are installed to improve ship motions and passenger comfort. This installation took place at Fort Lauderdale, where conditions were ideal for underwater operations: The sea was calm, the weather was sunny, and visibility was 10 meters. This is not always the case for our teams. They are trained to carry out repairs in even the harshest weather condition.

The entire operation was completed in just two days. This efficient timeline was made possible through careful planning and the expertise of our diver/technicians and our local support who assisted our team.

Preparation and mobilization

After the job was confirmed, we mobilized one of our skilled diver/technician teams to the ship’s location.

Upon arrival, the team coordinated an onsite meeting with all parties involved to finalize the procedure and address potential challenges. This preparatory phase was crucial for ensuring that the installation could proceed smoothly and without delays.

The T-Foil installation process

The installation of the T-Foil required a series of meticulously planned and executed steps to ensure accuracy and stability.

Before the installation could start, the external protection plugs on the hull were carefully removed. This preparatory step was vital to provide a clear surface for the new equipment, and it was carried out with precision to avoid any potential damage to the vessel’s structure. The removal of these plugs ensured that the T-Foil could be properly aligned and securely attached.

With the area prepared, our diver/technicians installed the threaded bars required to fasten the T-Foil. This phase involved precise underwater work, as the correct alignment of the threaded bars was essential for maintaining the stability of the installed unit.

Once the preparatory tasks were completed, the T-Foil was lifted using specialized equipment designed to maintain stability during the hoisting process. It was then carefully lowered into the water. Our team made sure that the unit remained steady and correctly oriented while positioning it.

After the T-Foil was in place, the final step involved securing it using tack welding. The welding process was executed with great care to ensure that the T-Foil would remain firmly anchored, maintaining the vessel’s hydrodynamic efficiency.

Final inspection and completion

Following the installation, the Hydrex team conducted a thorough inspection to confirm that the T-Foil was properly secured and aligned. All work was evaluated and approved by the involved parties, confirming that the job was performed to the highest standards.

The Hydrex approach

Performing complex underwater installations requires a blend of technical expertise, experience, and high-quality equipment. Our technical experts have extensive experience with underwater repairs and installations, and we use the best equipment available, all of which allowed our team to execute the T-Foil installation efficiently and safely. By performing the entire operation afloat, we eliminated the need for drydocking, significantly reducing costs and ensuring that the vessel stayed operational.

Conclusion

This operation is a good example of our commitment to precision and efficiency in underwater interventions.

Hydrex continues to set industry standards for underwater maintenance and repairs. Our team of highly skilled diver/technicians is equipped to perform a wide range of underwater services, including repairs, maintenance, and complex installations, all while keeping your vessel afloat and operational. Whether it’s bow thruster maintenance, propeller modifications, hull repairs, or any other underwater intervention, we have the expertise, experience and equipment to get the job done efficiently and safely.

Trust Hydrex to keep your fleet running smoothly, wherever you are in the world. Contact us today to learn more about our comprehensive underwater repair and maintenance solutions, and discover how we can support your operations with minimal downtime.

Hydrex: Your partner in keeping vessels afloat and on schedule.

If you have any questions regarding a possible underwater repair, do not hesitate to contact us. We are at your disposal 24/7 and ready to mobilize almost immediately.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more underwater case studies.

Underwater propeller cone fin installation offers immediate fuel saving

Underwater bow thruster removal in Rotterdam

Scrubber overboard pipe repairs in the Netherlands, France and Spain

Propeller blade modifications in Estonia

Propeller blade cropping in Ghent avoids costly drydocking