In August one of our diver/technician teams carried out several repairs during one operation on a 288-meter tanker. Work on the propeller blades, net catcher, rope cutters, split ring and rope guard was performed simultaneously during the ship’s stop in Cádiz, Spain.

By combining these repairs into one operation we brought the needed time frame down to the absolute minimum. It is a good example of the flexibility of services we offer our customers. We adapt our work to your schedule and can easily adjust to changing circumstances.

We can also split up a repair in several stages that can be carried out in the same port during repeat visits or in different ports. This might be needed if a repair is too complex to perform during one stop or if a ship only has a very short window, as is often the case with cruise ships or ferries that only make a short stopover in each port.

Our divers are trained to be flexible and to adjust to the specific circumstances of an operation.

Working on the seal assembly and propeller blades

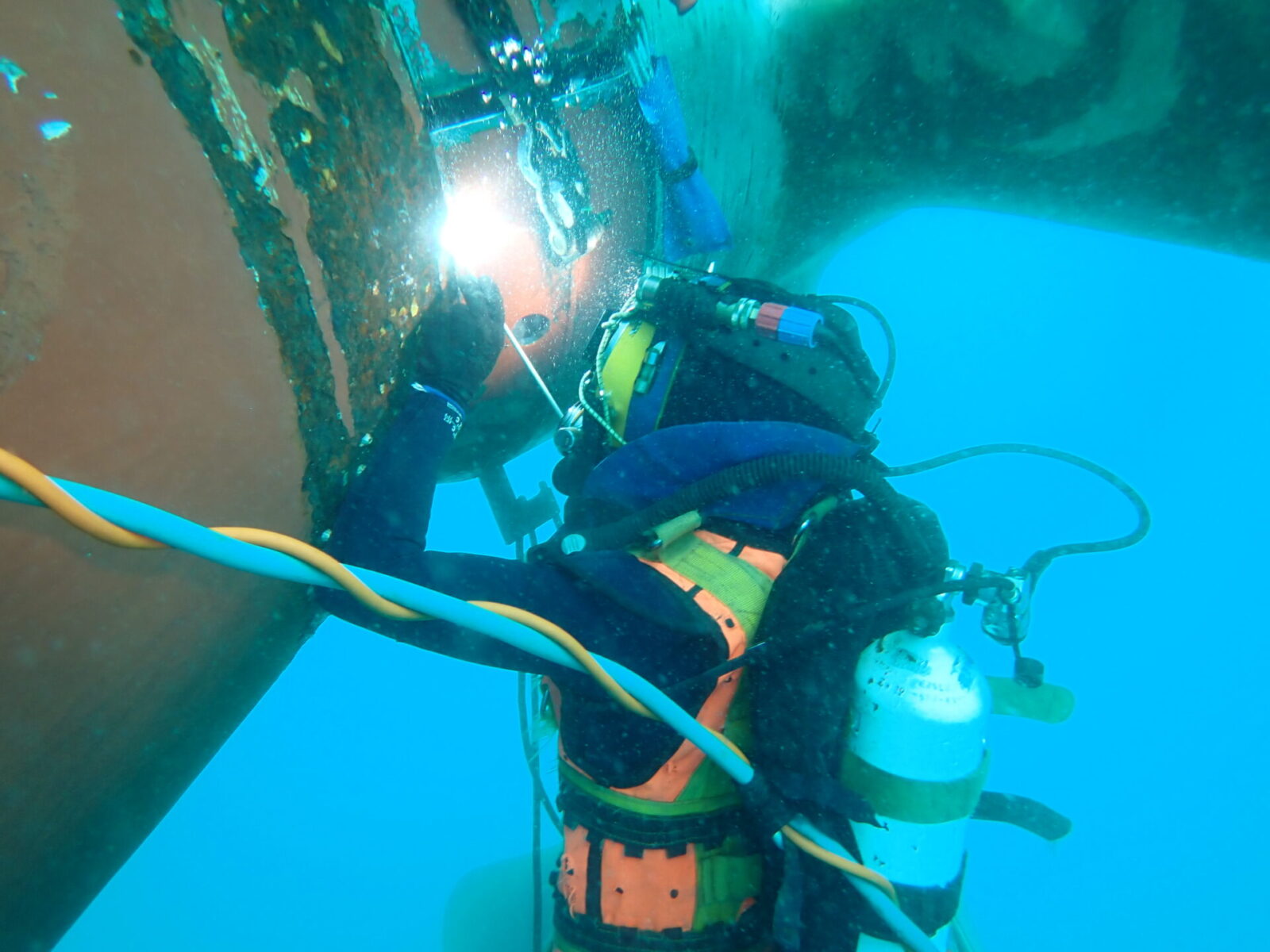

The team mobilized to the tanker’s location and started the operation with a detailed underwater inspection. This revealed damage on several parts of the stern underwater gear of the ship.

All five blades of the ship’s propeller had suffered scraping marks, nicks, cracks or small bends. The team ground out the damage and smoothed the edges. This optimized the propeller’s efficiency.

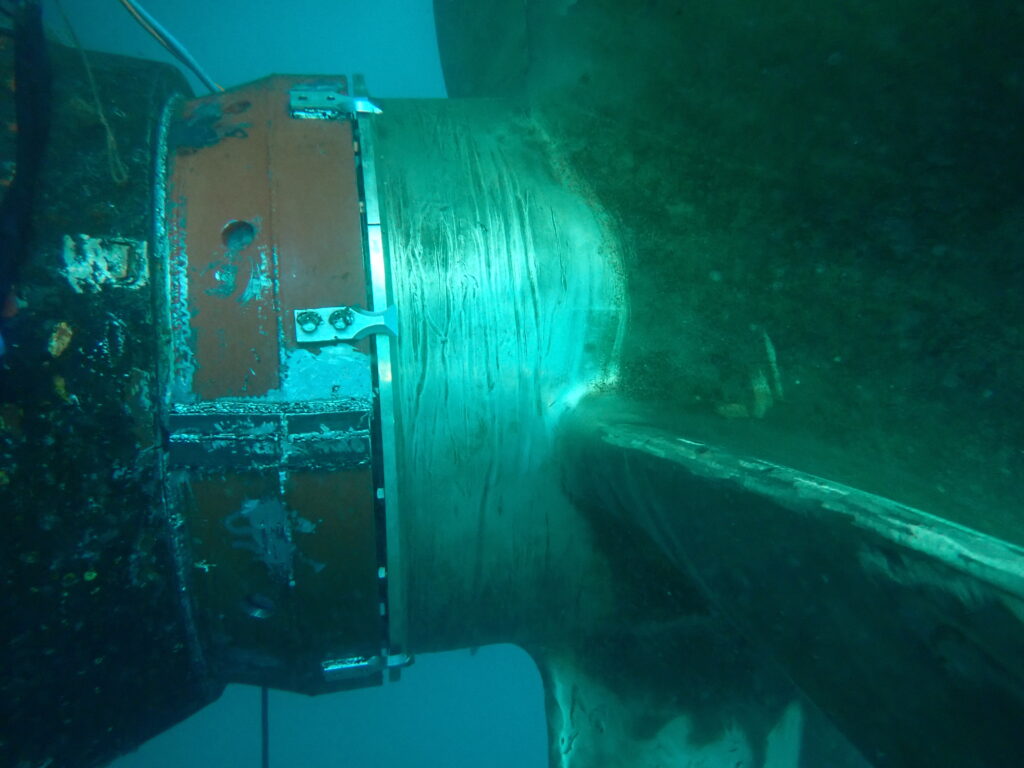

The propeller boss and the spinner cone were also lightly damaged, but no repair was deemed necessary on these areas.

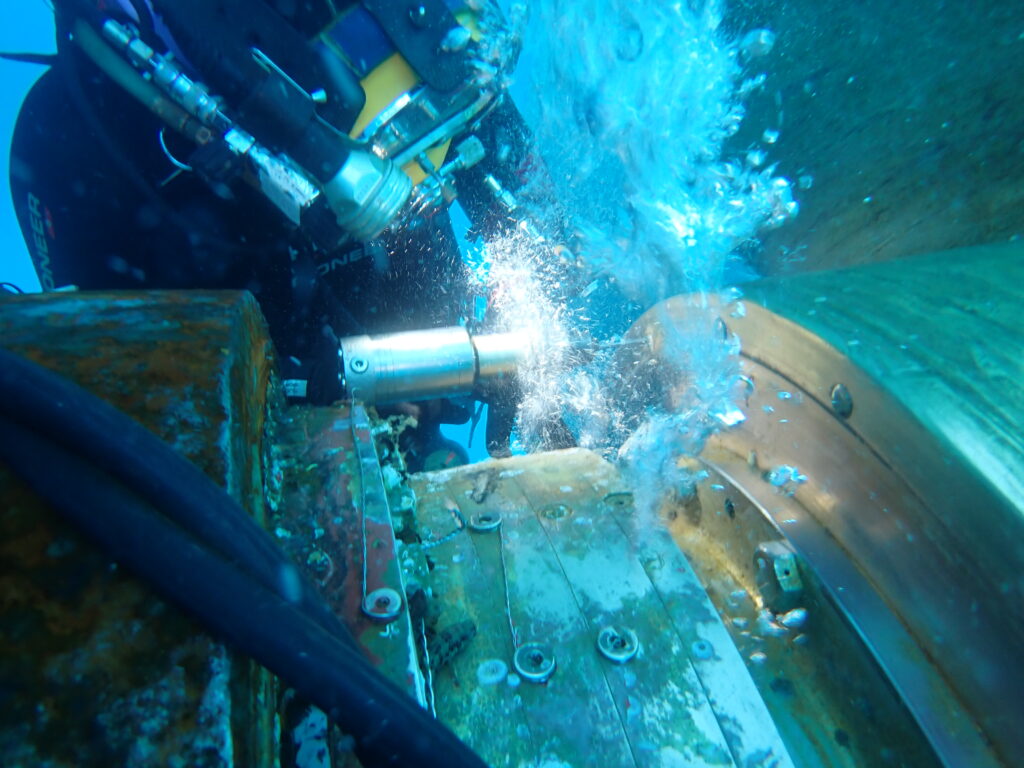

The port side stern tube seal assembly of the ship was damaged in several locations. The rope guard had been hit by some object and the bolts of the net catcher were broken. Both needed to be replaced. The split ring had also been damaged and forced out of alignment. Our divers replaced one half of the ring, realigned it and installed new plugs.

(the article continues below the pictures)

Finally, on the starboard side, a fishing line was removed from the rope guard and three new rope cutters were installed.

Conclusion

Like all projects we undertake, we took on, organized and executed the entire job, start to finish. Throughout the operation we were in close communication with the customer, the classification society and other parties involved.

The owner could continue his voyage without a costly and time-consuming trip to drydock.

If ever you need assistance with the underwater part of your vessel, give us a call. We can then tell you if the repair is feasible and start working on its handling.

+32 3 213 53 00

hydrex@hydrex.be

Click on the images below for more case studies.

Underwater stern tube seal replacement avoids drydock

Underwater bow thruster removal and reinstallation in Naples

Start saving fuel with your propeller cone fin now

Scrubber overboard pipe operations on sister vessels in Denmark

Permanent underwater insert repair on bulker in France